- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

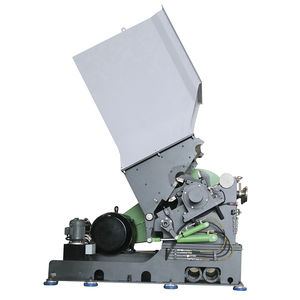

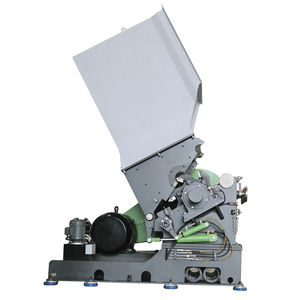

Single-roller crusher GE500/700stationaryhigh-capacityfor all materials

Add to favorites

Compare this product

Characteristics

- Technology

- single-roller

- Mobility

- stationary

- Other characteristics

- high-capacity, for all materials, for expanded polystyrene, EPS

Description

GE Series Economy Crusher

This series can provide different rotor designs. The rotor width covers 500mm to 1400mm. The rotor adopts high-efficiency double-scissor cutting technology. The welded cavity of the entire steel structure is combined with the V-shaped rotor to ensure stable machine operation and reliable performance. The compact body design facilitates cavity maintenance, quick cleaning and replacement of rotary knives, fixed knives and screens.

GE series economical crusher is suitable for on-line recycling of plastic production lines. It has special cutting technology to recover various small hollow materials, including injection mold parts, blow mold parts, profiles, sheets, films and other

materials. The recycled flakes are uniform.

Item(unit):GE500/500

Rotor diameter(mm):500

Rotor width(mm):700

Chamber size(mm):540*700

Number of rotor knives(row):5

Number of stator knives(row):2

Standard screen(mm):>6

Motor Power(kw):37

Machine Length(mm):1330

Machine Width(mm):1910

Machine Height(mm):2510

Tough welded steel machine body

ACERETECH crusher’s body is made of special high strength welded steel to prevent shell cracking and excessive stress damage while running.

Uniform grinding

We have more than twenty different knife designs such as double-shear V-shaped cutting. They can achieve uniform particle size and less dust after crushing. Modular cutting chamber. Select suitable knives and screen according to material characteristics.

Alloy steel rotary and fixed knives are made by European supplier.

Stable Powertrain

The drive motor and gear box are of European brands, with high efficiency of energy utilization for long-term stable running.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Aceretech‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.