- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

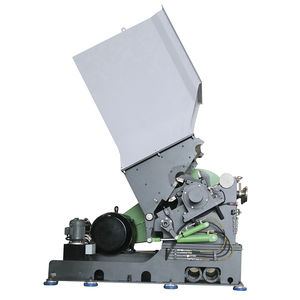

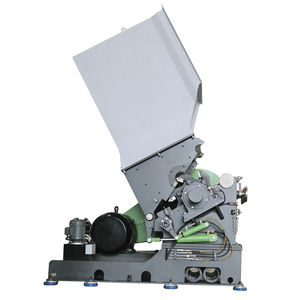

Single-roller crusher GF800/1600stationaryhigh-capacityfor all materials

Add to favorites

Compare this product

Characteristics

- Technology

- single-roller

- Mobility

- stationary

- Other characteristics

- high-capacity, for all materials, for expanded polystyrene, EPS

Description

GF500/1600 Cost Effective Crusher Recycle

GF series crusher is a high output and low energy consumption crusher specially designed for film, small hollow bottles and PET bottles. According to the characteristics of different material forms, this crusher is equipped with a variety of rotor models for choosing, the rotor diameter covers from 500-800mm, the minimum rotor width is 700mm, and the maximum is 1600mm. A targeted rotor structure can be designed to achieve the best crushing effect. The special welding process is used to integrally weld the steel structure, which can meet the demanding requirements and materials which are not easily broken. It also with large rotor bearings,tool holders and rotors. Standard V-shaped cutting technology is beneficial to improve cutting recycling efficiency and reduce dust content in recycled materials. The deflection wedge, a detachable attachment with a third knife, meets different crushing needs through simple disassembly. Other standard equipment includes an easy removing anti-wear plate in the crushing chamber and an external bearing to reduce the risk of contaminants entering the crushing chamber.

The output is relatively 20% - 40% higher than ordinary crushers. This machine has the characteristics of beautiful appearance, reliability and excellent cost performance.

Item(unit) - GF500/1600

Rotor diameter(mm):800

Rotor width(mm):1600

Number of stator knives(pcs):5*2/7*4

Number of stator knives(row):2

Chamber size(mm):800*1600

Motor power(kw):160

Machine Length(mm):3150

Machine Width(mm):2710

Machine Height(mm):3900

VIDEO

Catalogs

No catalogs are available for this product.

See all of Aceretech‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.