- Production Machines

- Cutting Machine

- Slitting machine

- ACHENBACH BUSCHHÜTTEN GMBH & CO KG

- Products

- Catalogs

- News & Trends

- Exhibitions

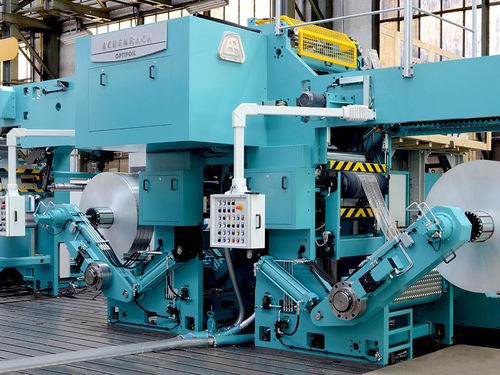

Slitting machine OPTIFOIL HEAVYSLIT®

Add to favorites

Compare this product

Description

Achenbach slitting machines type HeavySlit serve for slitting stronger aluminium as well as copper and brass foils huge finish rolls in narrow strips of minimum 10 mm width. Designed either with pivoted or horizontally shiftable rewinding unit they are always tailored to the specific operation purpose. For each new foil slitting machine or those to be modernized, a holistic approach to perfectly synchronize mechanics, hydraulics, automation and drive technology in their complex interaction is applied.

The cloud-based platform Achenbach OPTILINK® opens the way to the overall system networking of the various value creation stages and therefore to the optimization of the entire production process.

HeavySlit generally comes in two different designs:

with swivel winder

with horizontally movable winder

Every HeavySlit features very short material transport paths and a highly precise slitting device, equipped with either shear-cut or rotary shear-cut technology. Material feeding and finished roll handling are highly customizable.

Adaptive rewinding and pressure system with four operation modes

Stable, highly precise slitting cassette with optional axial micro-adjustment

Patented single contact roller system at the rewinder

Integrated oil applicator with individually adjustable oil application rollers

Rewinding concept mechanically decoupled from the main machine

Automatic integration of following further processing ans packaging systems

Quick changing device for winding shafts

The Achenbach HeavySlit® produces finished rolls as the starting material for end products such as:

Heat exchanger fins

Tube stock

Semi-rigid food containers

Closure stock

Other ACHENBACH BUSCHHÜTTEN GMBH & CO KG products

ACHENBACH OPTIFOIL® FOIL SLITTING MACHINES

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.