- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

2-axis laser alignment system AT-400shaftmeasurementindustrial

Add to favorites

Compare this product

Characteristics

- Technology

- 2-axis laser

- Applications

- shaft, measurement, industrial

- Protection level

- IP65, robust

Description

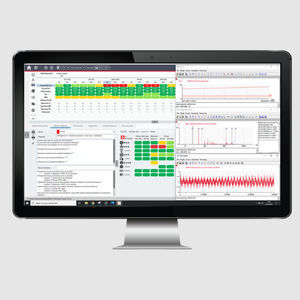

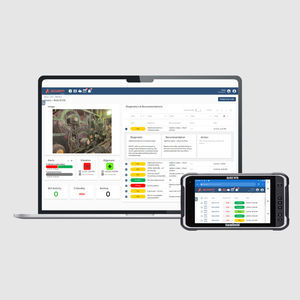

ACOEM AT-400: ELEVATE YOUR PRECISION WITH OUR HIGH-END DUAL-AXIS SHAFT ALIGNMENT SOLUTION

Its Dual Sweep method captures accurate measurements during shaft rotation, ensuring optimal alignment. Benefit from Dual Multipoint for diverse scenarios, capturing multiple points for precise calculations. Cloud connectivity streamlines report sharing, while the lifetime warranty underscores reliability.

Trust the Acoem AT-400 for robust dual-axis sensors and unparalleled versatility. Explore various measurement programs for horizontal, vertical, flatness, and soft foot conditions.

Features

SIMULTANEOUS HORIZONTAL AND VERTICAL MEASUREMENTS

Acoem M9 & S9 sensors excel in measuring both dimensions concurrently, offering comprehensive insights.

HIGH RESOLUTION

Achieve unmatched precision with a 0.001mm resolution, capturing even the smallest variations for analysis.

THINNESS AND LIGHTNESS

The thinnest 2-axis sensors at 305g, ensuring easy integration and mobility.

GENEROUS MEASUREMENT RANGE

Acoem M9 & S9 sensors cover up to 20 meters (65 ft) without compromising accuracy.

THOUGHTFUL DESIGN

Equipped with sliding covers, our sensors ensure product longevity and protection during storage.

LARGE DETECTOR EXCELLENCE

A substantial 20x20 mm² size and 0.001mm high-resolution capability make this detector ideal for demanding measurement tasks.

Dual precision at every turn: measuring methods for industry leaders.

Discover precision like never before with our advanced measuring methods. Engineered to perfection, these techniques redefine accuracy in alignment assessments.

Dual Sweep Method: Automated alignment evaluation for coupled machines, ensuring precision with every sweep.

Catalogs

Related Searches

- Alignment system

- Laser alignment system

- Shaft alignment system

- Alignment tool

- Laser alignment tool

- Measurement alignment system

- Automatic alignment system

- Wireless alignment tool

- Shaft alignment tool

- IP67 alignment system

- Pulley alignment system

- Standard alignment system

- Industrial alignment system

- IP65 alignment system

- Measurement alignment tool

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.