- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Laser alignment system AT-200shaftmeasurementindustrial

Add to favorites

Compare this product

Characteristics

- Technology

- laser

- Applications

- shaft, measurement, industrial

- Other characteristics

- automatic

Description

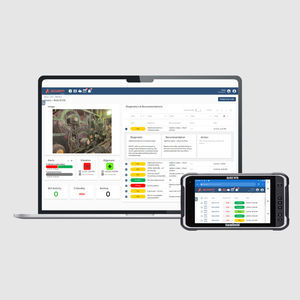

AT-200: The Alignment Solution for Horizontal or Vertical Machines with Coupling

This new generation of laser shaft alignment solutions is the result of nearly 40 years of expertise and innovation.

With integrated apps, customized technology features, and easy connectivity, the AT-200 enhances your user experience and boosts the efficiency of your maintenance teams. Delivering unmatched measurement performance and rapid, precise alignment, the AT-200 improves measurement and reporting capabilities to help extend the lifespan of critical machinery.

Features

DIGITAL SENSOR DETECTORS

Large 30 mm digital sensor detectors capable of handling long measurement distances and significant angular misalignment errors.

SOFTCHECK™ - SOFT FOOT DETECTOR

Easily verify the presence of soft foot to ensure reliable alignment.

FEETLOCK™ - AUTOMATIC GUIDANCE

Enhanced automatic guidance for base-bound or bolt-bound situations.

VERTIZONTAL™ - ALIGN MACHINES IN ONE MOVE

Align machines in both horizontal and vertical directions in one move, saving time.

TOLERANCES - AUTOMATIC QUALITY ASSESSMENT

Automatic assessment of alignment quality based on industry-standard tolerances.

MULTIPLE FEET FUNCTION

Useful for machines with more than two pairs of feet, ensuring proper alignment.

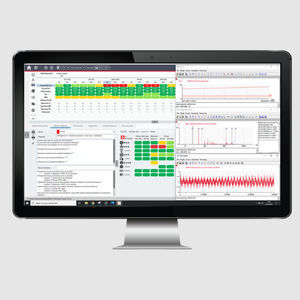

GUIDEU™ - INTUITIVE 3D GRAPHICAL USER INTERFACE

Easily align rotating assets using the visual Acoem GuideU™ interface.

TRUE LIVE™ - REAL TIME POSITIONING

Obtain the position of both shafts in real-time with Acoem True Live™.

SENSOR TECHNOLOGY - REMOVE DISTURBANCE

Eliminate disturbances from the industrial environment (light, vibration) using smart digital filtering provided by our sensor technology.

Catalogs

Related Searches

- Alignment system

- Laser alignment system

- Shaft alignment system

- Alignment tool

- Laser alignment tool

- Measurement alignment system

- Automatic alignment system

- Wireless alignment tool

- Shaft alignment tool

- IP67 alignment system

- Pulley alignment system

- Standard alignment system

- Industrial alignment system

- IP65 alignment system

- Measurement alignment tool

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.