- Materials - Tools - Components

- Standard Mechanical Component

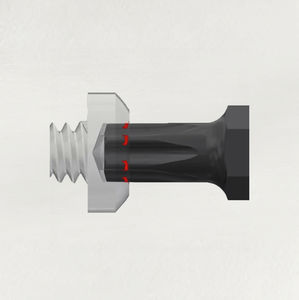

- Locking nut

- Acument Global Technologies

Pre-coated nut Strux®coatingthreaded

Add to favorites

Compare this product

Characteristics

- Types

- pre-coated

- Material

- coating

- Other characteristics

- threaded

Description

FOR CLINCH APPLICATIONS

Our high-performance Strux® Nut fasteners offer a stronger and more reliable assembly alternative to traditional clinch nuts. In most cases, a Strux® fastening solution will yield significant time and cost savings when compared to welded or other staked fasteners.

FEATURES

► Heat treated to SAE grades, ISO classes or to your own specifications

► Displacement lobes

► Can be used where welding is impossible or undesirable, such as joining dissimilar materials, pre-coated sheets or high strength thin

sheet materials

► Unlike spot welding, joints can be created in-die with clinch fasteners and automated installation equipment

► Can be installed after the painting or coating process without aesthetic damage barrier for displaced material

► Easy installation and simple visual inspection

BENEFITS

► Fast and easy installation

► Simple tooling

► High torsional resistance

► High push out resistance

► Consistent performance

► Can be installed in stamping die

► Improved positional tolerances as compared to weld studs and nuts

► Eliminates the assembly problems and high cost traditionally associated with weld fasteners

► Weld splatter

► Excessive heat

Catalogs

Strux® Fasteners

2 Pages

Fastening Solutions

13 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.