- Materials - Tools - Components

- Standard Mechanical Component

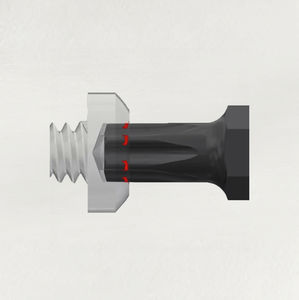

- Stainless steel fastening element

- Acument Global Technologies

Sheet metal fastener Techniclean™stainless steelcustom

Add to favorites

Compare this product

Characteristics

- Applications

- for sheet metal

- Material

- stainless steel

- Other characteristics

- custom

Description

FASTENERS FOR TECHNICAL CLEANLINESS

As pneumatic, hydraulic and powertrain systems become more complex, they also become more susceptible to failures resulting from particle contamination. These failures can lead to excessive repair or replacement costs, which are driving manufacturing companies to seek out solutions to help prevent harmful particles from entering the system. To support these efforts, Acument Global Technologies developed and defined our own unique standard and classes of clean fasteners under the brand name TECHNICLEAN™. Conventional fasteners are bulk processed through equipment shared with other products, meaning the job is only as clean as the dirtiest part. Furthermore, many fasteners have specified finishes that aren’t conducive to meeting technical cleanliness requirements. TECHNICLEAN™ fasteners are manufactured with Acument Global Technologies industry leading processes and fastener finishes designed to help provide and ensure cleanliness levels superior to that of conventional fasteners.

FEATURES

► Innovative Acument TECHNICLEAN™ process designed to meet your cleanliness needs

► Standard Acument TECHNICLEAN™ 600 and TECHNICLEAN™ 900 or custom defined particle cleanliness service levels

► Clean finish options include phosphate and zinc electroplate

► Custom finish options can be evaluated upon request

► Routine cleanliness inspections based on ISO 16232

BENEFITS

► Helps minimize the risk of damage caused by particle contamination

► Provides for a consistent and defined level of product cleanliness quality with or without finish options

Catalogs

No catalogs are available for this product.

See all of Acument Global Technologies‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.