- Power Transmission - Mechanical components

- Mechanical Transmission

- Industrial drive system

- Acument Global Technologies

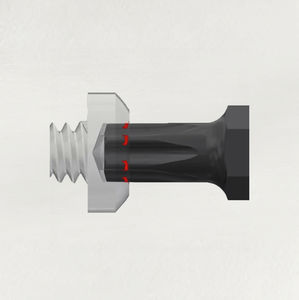

Industrial drive system TORX®

Add to favorites

Compare this product

Characteristics

- Product applications

- industrial

Description

The TORX® Drive System was specifically designed to provide a simple, cost-effective solution to the problems inherent in the process of installing and removing fasteners. Used in a multitude of industries, the TORX® Drive System can enhance product reliability, increase productivity and reduce total assembly costs – all if which are keys to remaining competitive in today’s marketplace.

FEATURES

► 15 ̊ drive angle

► Straight, vertical sidewalls

► Broad contact surface

► Standard drive tools for screw sizes inch (#000 – 1.375”) and metric (0.9mm – 36mm)

► Wide variety of sizes ranging from T1-T100, E4-E44

BENEFITS

► Greater depth of tool and lobe engagement while minimizing tool slippage

► No camout forces are created to push the driver up

► Since camout is virtually eliminated, little to no end load is required

► High torque transfer and drastically reduced radial forces resulting in longer tool life

► Driving forces spread over a broad surface

► Ability to convert to metric later without a tooling change

► Quality enhanced through single sourced gaging program

Catalogs

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.