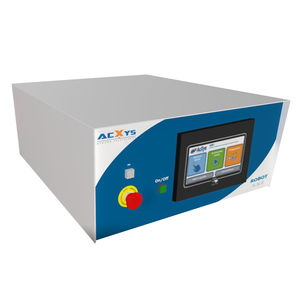

Plasma surface treatment machine ULS OMEGA seriesatmosphericPC-controllable

Add to favorites

Compare this product

Characteristics

- Type

- plasma

- Other characteristics

- PC-controllable, atmospheric

Description

ULS OMEGA has all the interfaces and flexibility required to integrate plasma technologies into complex scientific or industrial environments. This is the ideal equipment when the parameters of plasma processing need to be monitored and controlled and there is a need to interact with other equipment of the production line.

The OMEGA ULS is available as standard with 1, 2 or 3 nozzles to increase the processing capacity according to the cycle time requirements.

ULS OMEGA is available with 1, 2 or 3 nozzles to leverage the capacity of treatment in accordance with cycle durations.

ULS modules are flexible and versatile – they can accommodate a larger number of nozzles upon request – should large scale treatments be necessary.

ULS technology

– Easy to integrate, thanks to a small footprint and a compact nozzle.

– Localised, powerful “spot” or large area treatments.

– Operates in atmospheric or pressured ambient air.

– External monitoring via I/O signals, Modbus RTU on RS485 or Modbus TCP/IP

– Standalone or OEM version

Intuitive digital interface

– Integral Touchscreen

– Intuitive control

– Multilingual interface

– Error detection and troubleshooting

– Real time display of instructions

Compatible gas

– Air

– Nitrogen

– Other gas blend

Benefits of ULS technology

– Clear separation between material treatment and electrical discharge

– Safe from electrical hazards

– Extra-large range of applications for any type of material

– Easy to install

– Control of Process parameter and settings

– Cost effective

VIDEO

Catalogs

No catalogs are available for this product.

See all of AcXys Technologies‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.