Parts parts washer 550 seriesimmersion

Add to favorites

Compare this product

Characteristics

- Applications

- parts

- Other characteristics

- immersion

Description

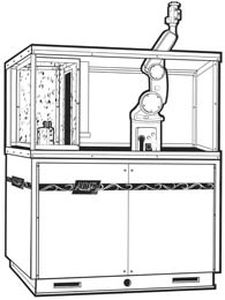

This washer is not what it appears to be. It is not a sandblaster, but a high pressure, glove box style, parts washer.

Because it is a manual type operation, it is one of the most versatile washers available.

The operator simply puts the part in the washer through the side door and washes the parts by manipulating the part and the wand with his hands through the gloves. The washer is activated with a foot switch. High pressure spray can be put into ports, cavities or directly sprayed on the part, for high pressure cleaning. With the ability to put the nozzle directly at the part, the full 3 GPM at 500 PSI force can be pin pointed to a small area on the part.

Biodegradable detergents and hot water are the cleaning solution used, which provides a safe and environmentally friendly solution. ADF detergents include rust inhibitor for steel parts and are safe on other materials such as brass, aluminum, stainless steel, copper, rubber, plastic or glass.

The wash solution passes through a 100 micron felt filter before returning to the reservoir and also passes through a high pressure filter between the pump and the nozzle. Therefore, dirt, chips and other contaminates are removed from the solution during every cycle. The washer has an extensive accessory list such as rinsing, oil skimming and others.

This washer is being used in a variety of applications including tool rooms, maintenance operations, low production and precision cleaning situations.

Catalogs

No catalogs are available for this product.

See all of ADF Systems, Ltd.‘s catalogsRelated Searches

- Automatic washing machine

- Spray washing machine

- Parts washing machine

- Spray booth

- Filter spray booth

- Extraction table

- Open spray booth

- Part spray booth

- Parts washer

- Welding downdraft table

- Parts parts washer

- Grinding process downdraft table

- Water spray booth

- Robotic washing system

- Immersion parts washer

- Mobile parts washer

- Custom downdraft table

- Dryer parts washer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.