- Metrology - Laboratory

- Metrology and Test Equipment

- Impedance tester

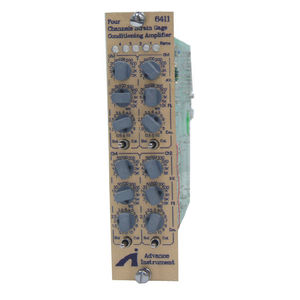

- Advance Instrument Inc.

Impedance tester GT2 insulation resistanceinstallationdigital

Add to favorites

Compare this product

Characteristics

- Test type

- insulation resistance, impedance

- Tested product

- installation

- Other characteristics

- digital

Description

After installing strain gage, the main quality verification and examination test are the isolation impedance and resistance shift.

The strain gage is made by foil alloy. Its isolation impedance after installing is more than 20 GΩ.

Use room-temperature curing adhesive, the gage resistance shift value must be less than 0.5%.

Use bake curing adhesive, the gage resistance shift value must be less than 2%.

When G. F. is 2, the resolution of GT2, being a strain indicator, is 2 με.

Features

● A compact instrument to verify the electrical quality of a strain gage installation before it is placed in service

● To read insulation resistance ( leakage ) to 20,000 MΩ with 15 VDC

● To measure the deviation of installed gage resistance from precise standard to a resolution of 0.0001%

● Ohmmeter scale to diagnose and solve questionable installations

● To verify the complete gage circuit including lead-wires

Catalogs

GT2 Gage Installation Tester

2 Pages

A.I.-Catalog_2013

120 Pages

Other Advance Instrument Inc. products

Strain Gauge Measuring Instruments

Related Searches

- Test machine

- Measuring device

- Test stand

- Material testing machine

- PC-controllable testing machine

- Compression test machine

- Vertical test machine

- Universal test machine

- Digital measuring device

- Tensile test machine

- Flexure testing machine

- Digital testing system

- Laboratory test machine

- Electromechanical test machine

- Fatigue test machine

- Quality control test machine

- PC-controllable test bench

- Test set

- Shearing testing machine

- Mechanical test machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.