- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

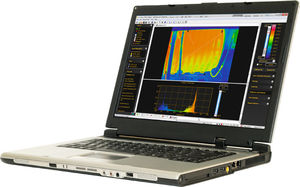

Camera system for the glass industry FurnaceSpectionfor furnacesmonitoringthermal imaging

Add to favorites

Compare this product

Characteristics

- Applications

- for the glass industry, for furnaces

- Function

- monitoring, thermal imaging

- Spectrum

- infrared

- Interface

- Ethernet

- Other characteristics

- rugged, cooled, high-temperature, IP66

Description

Infrared Camera System for Continuous Reformer Tube Monitoring and Temperature Measurement Inside Furnaces

Advanced Energy's FurnaceSpection system provides real-time continuous temperature measurement to identify process abnormalities inside high-temperature furnaces in refining, metals, and glass production processes. It measures the temperature of product, refractory, and heat transfer surfaces inside natural gas-fired furnaces.

•Accurate 640 x 480 focal-plane array thermal imaging camera with sensitivity of 0.06°C

•Boroscope optics filtered at 0.85 μm wavelength to view through combustion gas and flames

•Rugged IP66, air or water cooled (SD), protective enclosure

•Standard (SD) with auto-retraction and Mobile (MB) versions available

•Radiometrically calibrated

Overview

The FurnaceSpection™ system helps you quickly and accurately identify process abnormalities to prevent unplanned outages. Monitor and control process temperature uniformity through streaming images and powerful software that is also ideal for analysis and historical trending. Digital and analog outputs are available to broadcast images of your plant’s local network.

For petrochemical reformers, FurnaceSpection ensures tubes perform optimally and helps extend their life cycles. In metal annealing applications, use FurnaceSpection cameras to reduce cycle times and improve quality and process repeatability.

In addition to standard (SD) and mobile (MB) versions, customized solutions are available to meet specific application needs.

Benefits

•Monitor and control process temperature uniformity through real-time streaming images

VIDEO

Catalogs

Petrochemical Solutions Brochure

16 Pages

Glass Solutions Brochures

20 Pages

Related Searches

- Digital camera module

- Infrared imager

- Surveillance camera

- Waterproof camera system

- Detection imager

- Compact imager

- Thermal camera

- Gigabit Ethernet camera

- Robust camera

- Temperature-controlled camera

- High-performance camera module

- Ethernet imager

- Real-time monitoring device

- Uncooled camera module

- Temperature monitoring device

- IP66 camera system

- Microbolometer camera module

- Cooled camera module

- Near-infrared camera

- PAL/NTSC camera system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.