- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Storage tank camera system CVMmonitoringthermal imaginginfrared

Add to favorites

Compare this product

Characteristics

- Applications

- for storage tanks

- Function

- monitoring, thermal imaging

- Spectrum

- infrared

- Sensor

- focal plane array, microbolometer

- Interface

- gigabit Ethernet

- Other characteristics

- with real time viewing (RTV)

Description

Turnkey Solution for Monitoring Critical Vessels

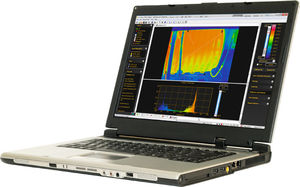

Advanced Energy's ThermalSpection CVM system uses non-contact thermal imaging to provide real-time, continuous, automated fault detection and monitoring for your critical assets.

•Early fault detection to reduce risk, emergencies and unplanned outages

•Continuous, automated monitoring

•Easy integration into existing plant DCS and data historian

•Designed for hazardous area installations (ATEX, Class I Div 2)

Overview

Identify problems before they become emergencies.The ThermalSpection™ CVM infrared imaging system offers real-time, continuous fault and hot-spot monitoring. And it's ideal for monitoring critical vessels (e.g. gasifier skin temperature).

The ThermalSpection CVM system can be customized, is fully digital, and uses standard Ethernet LAN. This allows easy and cost-effective transfer of digital image data to control rooms. Additionally, the LumaSpecTM software has modules that support output via Modbus or OPC to the plant’s DCS.

Benefits

•Reduce risk and unplanned outages

•Utilize advanced features in a user-friendly interface

•Capture thermal data snapshot frames at set intervals or trigger using temperature alarms

•Easily integrate into existing plant DCS and data historian

Features

•Automatic hot-spot tracking feature

•HTML visualization displays for broadcast on plant intranet

•Data Historian archive

•OPC/Modbus interface

•Optional integration with OSIsoft’s PI database system

Catalogs

Related Searches

- Digital camera module

- Infrared imager

- Surveillance camera

- Waterproof camera system

- Detection imager

- Compact imager

- Thermal camera

- Gigabit Ethernet camera

- Robust camera

- Temperature-controlled camera

- High-performance camera module

- Ethernet imager

- Real-time monitoring device

- Uncooled camera module

- Temperature monitoring device

- IP66 camera system

- Microbolometer camera module

- Cooled camera module

- Near-infrared camera

- PAL/NTSC camera system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.