- Machine-tools

- Machine Tool Accessory

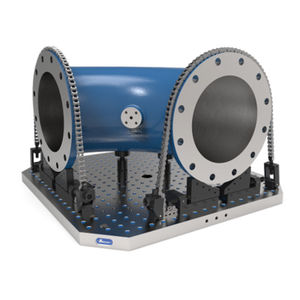

- Fixture system

- Advanced Machine & Engineering

Positioning fixture S.A.F.E

Add to favorites

Compare this product

Characteristics

- Options

- positioning

Description

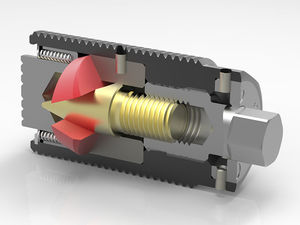

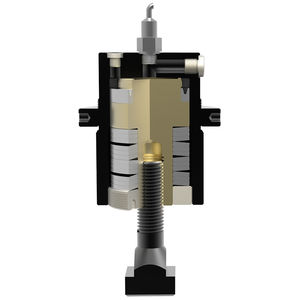

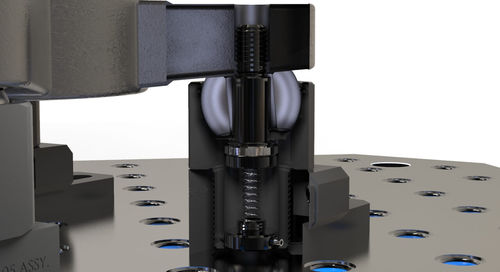

INVERTED STUD BALL ELEMENT ALLOWS FULL 5-SIDED MACHINING

Advanced Machine & Engineering’s (AME) new patent-pending inverted stud ball element allows full, five-sided profile machining that decreases overall machine time for a variety of industries including aerospace, medical, and automotive.

This self-aligning fixture element (S.A.F.E.) features:

A ball element that has 6 degrees of rotation in any direction.

Swiveling ball element contact pads that allow less internal stresses for bent or angled parts requiring clamping for machining.

Viton O-Ring protection that prevents penetration of chips and coolant within the ball element system guaranteeing long life.

Fixed and adjustable threaded ball element heights.

Fixed Press Fit ball element heights for locating and positioning.

Custom sizes available upon request.

The ball element and stud combination provides a one-component design for stress-free clamping by conforming right to the part that is being machined.

VIDEO

Catalogs

SPIETH Catalog

100 Pages

AMROCK Modular Workholding

80 Pages

Other Advanced Machine & Engineering products

Tombstones, Custom Fixtures & Workholding Components

Related Searches

- Chuck

- Clamp

- Vice

- Machine vice

- Turntable

- Electric turntable

- Machine tool vice

- Machining tool holder

- Horizontal turntable

- Workholding component

- Motor-driven turntable

- DIN chuck

- Hydraulic clamping device

- Mechanical workholding component

- DIN tool holder

- Machine tool turntable

- Compact vice

- Self-centering vice

- Zero-point clamping unit

- Machining workholding component

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.