- Packing - Handling - Logistics

- Handling and Lifting

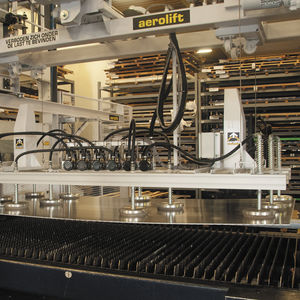

- Sheet metal vacuum lifting device

- Aerolift Industrials B.V.

Sheet metal vacuum lifting device horizontal

Add to favorites

Compare this product

Characteristics

- Product applications

- for sheet metal

- Type

- horizontal

Description

Aerolift designs customised lifting solutions to handle all kind of products, including metal plates. Both magnetic and non-magnetic metals can be safely lifted by vacuum. Think of steel, aluminium, copper, stainless steel and other metal alloys. Compared to other lifting system vacuum technology offers several advantages no matter the weight of size of the load!

Non-magnetic metals are often handled with chains or clamps, with surface damages as a result. Vacuum lifting technology offers distinct advantages:

-No damage to the load;

-Faster handling with less manpower;

-No spacers or stoppers needed for storage.

Magnetic metals are often handled by magnets and other traditional systems. Vacuum lifting technology can boost the efficiency by:

-Increased lifting capacity due to low-weight lifter;

-Lower capital investment;

-No heavy-duty backup power necessary;

-No residual magnetism;

-Perfect control on the plate to handle;

-No spacers or stoppers needed for storage;

-Free of magnetic interference and other environmental influences (think of ships compasses and gyros).

All Aerolift vacuum lifters comply with the most stringent safety standards. The lifting devices are equipped with controllable safety features. Improving the safety on the working place tremendously.

Catalogs

No catalogs are available for this product.

See all of Aerolift Industrials B.V.‘s catalogsOther Aerolift Industrials B.V. products

Metal plate lifting solutions

Related Searches

- Lifting system

- Vacuum lifting device

- Sheet metal vacuum lifting device

- Horizontal vacuum lifting device

- Plate vacuum lifting device

- Electric vacuum lifting device

- Handling lifting system

- Pivoting vacuum lifting device

- Heavy load vacuum lifting device

- Automatic vacuum lifting device

- Stone slab vacuum lifting device

- Concrete slab vacuum lifting device

- Heavy load lifting system

- High-speed vacuum lifting device

- Multi-product lifting system

- Lifting system with gripping tool

- Vacuum lifting device for the construction industry

- Overhead crane vacuum lifting device

- Secure vacuum lifting device

- Industrial vacuum lifting device

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.