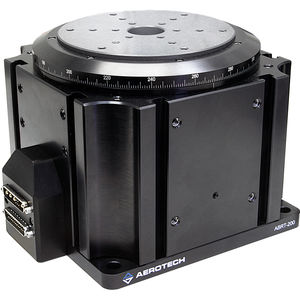

Linear stage AVS100/AVSI100 Seriestranslationlinear servo-motorsingle-axis

Add to favorites

Compare this product

Characteristics

- Orientation

- linear, translation

- Type

- linear servo-motor

- Number of axes

- single-axis

- Other characteristics

- precision, compact, closed-loop, ball screw

- Stroke

6 mm, 13 mm, 25 mm

(0.236 in, 0.512 in, 0.984 in)- Speed

50 mm/s

- Repeatability

0.75 µm, 1 µm

- Load

25 kg

(55.12 lb)

Description

Aerotech’s AVS100 and AVSI100 series stages offer a solution for applications that require very small incremental movements in elevation above a horizontal plane. Low profiles and precise motion capability make these stages ideal for use in semiconductor wafer inspection and testing, fiberoptics assembly and inspection, automated tool alignment, machine vision inspection systems and laser machining applications.

•Long-life linear guide bearing system

•Submicron closed-loop positioning

•Low-cost, high-performance stage

•Precision-ground ball screw

•Integral or removable motor

The AVSI100 series stages provide identical performance to the AVS100 stages, but in an even smaller footprint. The AVSI100 integrates the motor directly with the drive screw with no motor coupling. This makes the stage significantly shorter in length.

Quality Design Provides Superior Performance

The AVS100/AVSI100 series provides precise elevation of a load in a vertical plane. Rotational movement of a precision-ground ballscrew is converted into vertical elevation of the AVS100/AVSI100 series tabletop.

Sealed linear motion guide bearings with integral wipers are incorporated to provide excellent payload capability, long life, and smooth, precision motion. Stable and parallel vertical motion with no rocking or horizontal deviation of the platform is ensured.

Catalogs

AVS, AVSI100

7 Pages

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.