- Environment - Health - Safety

- Air Treatment and Noise Management

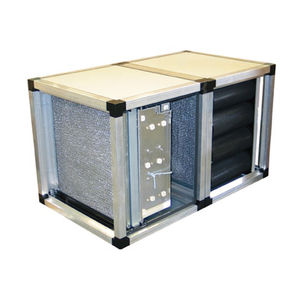

- Oil mist collector

- AERSERVICE EQUIPMENTS SRL

Oil mist collector

Add to favorites

Compare this product

Characteristics

- Application

- oil

- Flow rate

Max.: 30,000 m³/h

(1,059,440 ft³/h)Min.: 3,000 m³/h

(105,944 ft³/h)

Description

Purification system for oil mists with collection tank for any oil to be recycled

Purification of oil mists extracted in centralised systems. Thanks to the balance of cost vs. benefit, they are an excellent alternative to electrostatic filters.

This line of mechanical filters with progressive structure has been designed to eliminate entire or emulsified oil mist which, by way of example, could result from the use of operating machines such as lathes, grinders, milling machines and threading machines.

It is therefore used for the recovery of production areas, usually by fully centralising the extraction operations or working by area.

Structure constructed entirely in powder-coated welded steel, complete with doors closed by means of handles with a watertight lock ensuring tightness against both air loss and fluid leaks (oil).

A plenum is installed on the delivery side of the filter which is used to transport and slow airflow.

Filter section divided into 2 areas. One pre-abatement chamber equipped with dual stage metal filters for the first separation of the fluids which will be decanted into the lower collection tank and then the section with highly efficient filter medium(99% with filtration class EU6, DIN 24185 - EN 779) acting on particulate and any oil residue in the air flow.

Oil collection tank positioned below the two filter chambers both which can decant all fluids.

The chamber is emptied by means of a valve which is opened manually.

Catalogs

No catalogs are available for this product.

See all of AERSERVICE EQUIPMENTS SRL‘s catalogsRelated Searches

- Radial fan

- Ventilation fan

- Extractor fan

- Fan for industrial applications

- Steel fan

- AC fan

- Watertight fan

- Filtration system

- Dust collector

- Industrial fume extractor

- Panel pre-filter

- IP55 fan

- Exhaust fan

- Mobile fume extractor

- Filter industrial dust collector

- Backward curved fan

- Dust pre-filter

- Galvanised steel fan

- Bag filter

- Welding fume extractor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.