- Industrial machines and equipment

- Surface Treatment Equipment

- Grinding process downdraft table

- AERSERVICE EQUIPMENTS SRL

Polishing downdraft table BAfor grinding processes

Add to favorites

Compare this product

Characteristics

- Applications

- for polishing, for grinding processes

Description

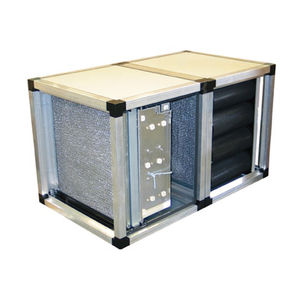

Down-draught benches

Extraction of welding fumes and particulate, sanding, grinding, iron, marble, plastic and all activities where there is a need to create a safe workplace for the operator and limit the area affected by particulate emissions.

The down-draught benches were designed in a range of sizes and accessories. This makes them exceptionally versatile for use in the extraction and filtration of air, the recovery of particulate in welding fumes and dust from grinding, deburring and polishing of components and items of a contained size and weight, as well as minor procedures of manual torch cutting.

Particularly suitable for welding schools and professional technical institutes.

- Painted steel load bearing structure of a suitable thickness, pre-configured for handling by means of a pallet jack, lift truck and/or securing to the floor. The sides of the structure are supplied with standard parts allowing the connection to the extraction fan or hose on both the right and left hand sides of the work surface.

- Sturdy consolidated extraction surface is modifiable, depending on the work to be carried out, by means of fitted guides which allow the ventilation slots to be increased or decreased.

- Removable front extractor fan panel, with removable side panels which can be opened by means of fitted hinges.

- Internal mechanical pre-filter section consisting of an anti-spark, cylindrical steel mesh filter.

- Sealed particulate containment drawers.

Catalogs

BAF-INDUSTRY

4 Pages

BA-INDUSTRY

4 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.