- Environment - Health - Safety

- Air Treatment and Noise Management

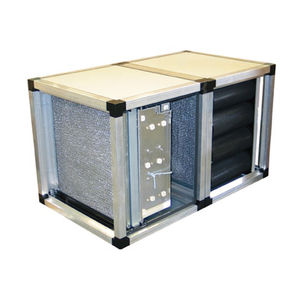

- Cartridge dust collector

- AERSERVICE EQUIPMENTS SRL

Cartridge dust collector IFC mechanical shaker cleaningcompactautomatic

Add to favorites

Compare this product

Characteristics

- Technology

- cartridge

- Backflushing

- mechanical shaker cleaning

- Other characteristics

- compact, automatic

- Output

Max.: 14,400 m³/h

(508,531.2008 ft³/h)Min.: 2,000 m³/h

(70,629.3334 ft³/h)

Description

Cartridge filter purification system with automatic cleaning for fumes and particulate

The cartridge filters have, for years, represented the ideal solution for the elimination of pollutants in the form of fumes and particulate generated by industrial and tertiary processes.

Thanks to the high level of filter surfaces, and the advanced cleaning system which guarantees longevity, they have more compact dimensions compared to classic sleeve filters, with a consequent savings in space and cost of installation, as well as that of maintenance.

The design of the IFC range takes account of the more restrictive environmental regulations and is therefore used in mechanical engineering, foundries, chemical and food industries, and the processes of welding, grinding and polishing, powder coating, and the various difficulties presented in dedusting when the volume of particulate to be separated is not particularly heavy-duty and where the amount of relative humidity is not too high.

Load-bearing structure in sturdy steel, powder-coated and equipped with self-supporting panels which can be removed for maintenance operations, resting on sturdy support legs.

Filter section consisting of the Plenum for air with high volumes of particulate housing the filter cartridges, positioned between the upper chamber into which the clean air is conveyed and the lower hopper for particulate transfer.

A compressed air cleaning device consisting of a certified compressed air accumulation tank, diaphragm valves with ultra- fast response time and relative Full-Immersion piloted solenoid valve.

Catalogs

No catalogs are available for this product.

See all of AERSERVICE EQUIPMENTS SRL‘s catalogsRelated Searches

- Radial fan

- Ventilation fan

- Extractor fan

- Fan for industrial applications

- Steel fan

- AC fan

- Watertight fan

- Filtration system

- Dust collector

- Industrial fume extractor

- Panel pre-filter

- IP55 fan

- Exhaust fan

- Mobile fume extractor

- Filter industrial dust collector

- Backward curved fan

- Dust pre-filter

- Galvanised steel fan

- Bag filter

- Welding fume extractor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.