- Environment - Health - Safety

- Air Treatment and Noise Management

- IP55 fan

- AERSERVICE EQUIPMENTS SRL

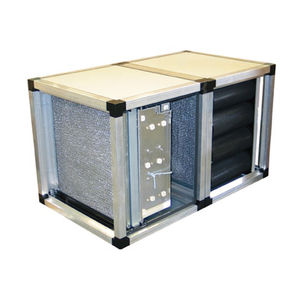

IP55 fan RCcentrifugalsuctionsteel

Add to favorites

Compare this product

Characteristics

- Type

- IP55

- Configuration

- centrifugal

- Function

- suction

- Material

- steel

- Applications

- for automotive applications

- Other characteristics

- single-inlet, backward curved

- Air flow

Min.: 470 m³/h

(16,597.893 ft³/h)Max.: 24,200 m³/h

(854,614.935 ft³/h)

Description

Centrifugal fans with backward curved blades in thick steel sheet metal

Extraction of air with a high volumes of particulate, exhaust gases, welding fumes, etc.

- Structure: The structure of the extraction fan is entirely manufactured from welded steel sheet metal of a suitable thickness which is then epoxy coated in RAL 7032 grey.

In addition to the support base for the electric motor, an additional seat can be requested secured to the suction nozzle to increase stability of the machine.

- Impellers: Employs epoxy coated backward curved impeller blades manufactured from thick galvanised, welded sheet metal, static and dynamic balancing according to ISO standards, keeping noise and vibration levels to a minimum.

- Motors: Three-phase asynchronous IE2 efficiency, normally 400V/50-60Hz IP55, in accordance with UNELMEC standards. Installed with 2, 4 or 6 poles depending on the required pressure, or with dual-polarity for two-speed versions.

It is designed to be assembled on a support base shared with the fan.

The power indicated in the performance tables have been sized taking into consideration machine performance and an additional safety margin to compensate for any system faults.

- Special versions: ATEX for environments with a risk of explosion regulated by Directive 94/9/EC.

Centrifugal fans with backward flat blades in thick steel sheet metal

Catalogs

Related Searches

- Radial fan

- Ventilation fan

- Extractor fan

- Fan for industrial applications

- AC fan

- Steel fan

- Watertight fan

- Filtration system

- Dust collector

- Industrial fume extractor

- Panel pre-filter

- IP55 fan

- Exhaust fan

- Mobile fume extractor

- Filter industrial dust collector

- Backward curved fan

- Dust pre-filter

- Galvanised steel fan

- Bag filter

- Welding fume extractor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.