- Industrial machines and equipment

- Welding and Assembly

- Fixed extraction arm

- AERSERVICE EQUIPMENTS SRL

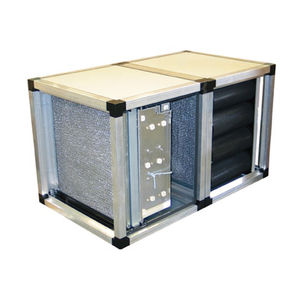

Fixed extraction arm ARMOFLEXwall-mountedflexiblearticulated

Add to favorites

Compare this product

Characteristics

- Mobility

- fixed, wall-mounted

- Type

- flexible, articulated

- Applications

- for welding fumes

- Other characteristics

- with hood

- Length

2,000 mm, 3,000 mm, 4,000 mm

(78.74 in, 118.11 in, 157.48 in)- Diameter

160 mm

(6.3 in)

Description

Articulated extraction arm for the removal of welding fumes and micro-particulate, self-supporting pantograph structure balanced with double sealed gas pistons, flexible hose

Extraction of fumes and micro-particulate from welding.

Wall or trolley installation are possible.

The Armoflex series, thanks to the materials used and its innovative design, provides the operator with high manoeuvrability and a stable position, guaranteed by a system of Belleville washers which supports the arm.

The internal load bearing structure is manufactured with re-enforced steel tubing and 6061 aluminium components CNC machined from single blocks to achieve T6 properties, then anodised to guarantee durability over time, despite continuous exposure to fumes.

The flexible cover hose is a multilayer PVC to guarantee protection from any sparks and resistance to high temperatures (max 140 ° C).

The extraction hood, with high uptake for maximum efficiency of extraction, includes a manual damper to regulate airflow, anti-intrusion grille protection and handle.

The ARMOFLEX series is available in three versions:

IBFA: wall-mounted version, supplied with a painted steel bracket for fastening and connecting to the exhaust fumes hose. Duct installation is possible without the shelf.

IBFAV: Version complete with centrifugal fan, for wall installation, supplied with a painted steel bracket for fastening and connecting to the exhaust fumes hose.

IBFAC: Version for use on a trolley or horizontal surface (e.g.: down-draught benches).

Catalogs

Related Searches

- Industrial fume extractor

- Mobile fume extractor

- Welding fume extractor

- Fume extractor with extraction arm

- Stationary fume extractor

- Extraction arm

- Dust fume extractor

- Cartridge fume extractor

- Fixed extraction arm

- Flexible extraction arm

- Compact fume extractor

- Smoke extraction arm

- Fume extractor with HEPA filter

- Dust extraction arm

- Wall-mounted extraction arm

- Welding fume extraction arm

- Extraction arm with hood

- Wall-mounted fume extractor

- Welding screen

- Rigid extraction arm

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.