- Electricity - Electronics

- Cable, Connector, Enclosure

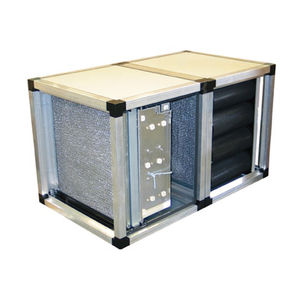

- Benchtop electric cabinet

- AERSERVICE EQUIPMENTS SRL

Benchtop electric cabinet RPI - M Seriesautomaticwith door

Add to favorites

Compare this product

Characteristics

- Mounting

- benchtop

- Other characteristics

- automatic, with door

Description

Automatic control system for extraction systems

The current international trend of giving greater importance to energy consumption, imposes the use of better technologies beginning right from the design stage.

Aerservice offers a series of items and devices able to reduce power consumption for a quick return on the initial cost and the benefit of future consumption.

Centralised air extraction is a typical example of the application of inverter systems and Aerservice offers three different solutions which range from manual regulation (RPI-M) to completely automatic (RPI-A).

The manual version is a solution to adopt when only the adjustment of fan speed is required, without any management of system start/stop.

In fact, air extraction is regulated as a function of the settings, with the damper open, via a single instrument for measuring differential pressure which transposes when extraction points open or close.

This type of system has short installation times. In fact, the only difference between a simple extraction system and a manually adjusted extraction system is the introduction of an electrical panel (which also serves as a protection for the extraction motor), which houses the inverter and the electronic differential measurement instrument.

- Automated fan management based on the extraction points which are in operation.

- Fan sized for the maximum number of simultaneous extraction stations (5 out of 10).

- Reduced diameters in the extraction circuit with decreased weight, fewer fixtures and less masonry work, etc.

- Notable savings in heated or air conditioned environments thanks to the optimised rates of extraction.

Catalogs

No catalogs are available for this product.

See all of AERSERVICE EQUIPMENTS SRL‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.