- Products

- Catalogs

- News & Trends

- Exhibitions

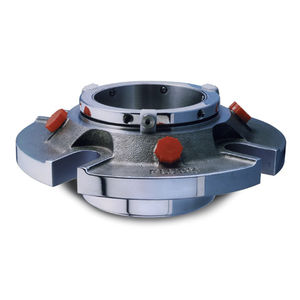

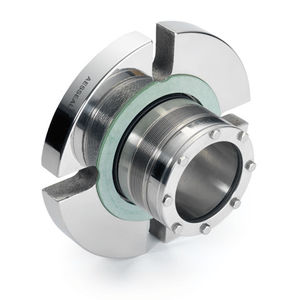

Spring mechanical seal CDFI & CDFCfor pumpmetalprocess

Add to favorites

Compare this product

Characteristics

- Type

- spring

- Applications

- for pump

- Material

- metal

- Domain

- process

- Other characteristics

- balanced, face, double, bi-directional

Description

Double Mechanical Seal

bridges the product range gap between and differentiating itself in two areas. The hybrid design offers a metal-to-metal inboard drive and an integral bi-directional pumping device, allowing the seal to fit in radial cross sectional spaces as small as 0.312" (8mm). The CDFI™ / CDFC™ is available in any AESSEAL® standard seal face and elastomer combination.

Features:

Integral deflector guides barrier fluid under faces and extends seal life

Incorporates highly effective bi-directional pumping ring to maximise barrier flow and increase seal life

Bi-Metal CDFI™ / CDFC™ options also include exotic allow wetted components at minimum price premium for use with corrosive chemicals

Hydraulically balanced seal-face technology for reduced power consumption

Non-shaft-fretting sleeve elastomer and positive set screw shaft drive

Independent seal face design to enhance safe containment of process fluid in the event of damage to any individual sealing element

Multiple spring seal face loading

Sizes available from 1.125" to 5.000" (28mm - 125mm) in standard and ANSI Plus gland formats

Directed Barrier Fluid Circulation

Removing the heat at the inboard faces is critical for any double mechanical seal. The CDFI™ / CDFC™ directed barrier fluid flow path achieves effective heat removal at both sets of seal faces.

Bi-directional Barrier Fluid Circulation

Developed using the highly efficient patented DMSF™ pumping ring the CDFI™ will effectively and reliably circulate barrier fluid irrespective of the direction of shaft rotation.

Related Searches

- Mechanical seal

- O-ring gasket

- Circular gasket

- Lip seal

- Pump mechanical seal

- Metal seal

- Metal mechanical seal

- Spring mechanical seal

- Cartridge mechanical seal

- Shafts seal

- Balanced mechanical seal

- Mechanical seal for the chemical industry

- Elastomer gasket

- Stainless steel gasket

- Static gasket

- Braided PTFE packing

- Water gasket

- Composite mechanical seal

- Face mechanical seal

- Carbon mechanical seal

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.