- Industrial machines and equipment

- Surface Treatment

- Aluminum anodizing

- A.G.C. BUSINESS CONSULTING S.A.

- Products

- Catalogs

- News & Trends

- Exhibitions

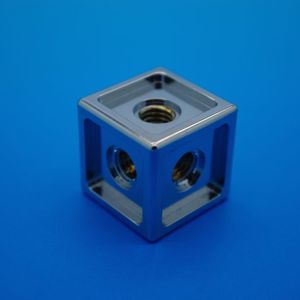

Aluminum anodizing for aeronauticsautomotivefor electronics

Add to favorites

Compare this product

Characteristics

- Type of substrate

- aluminum

- Applications

- for aeronautics, automotive, for electronics

- Other characteristics

- with coloring

Description

Our capacities in permanent mold gravity casting

Parts from hundredth of grams to several thenth kilograms

Available materials :

Aluminum

Magnesium

Zamak

Anodisation

3 and 4 axis machining centers

Assembly possiblity

What is permanent mold casting ?

Permanent mold gravity casting is a process of pouring melted metals in a steel mold. By cooling down the metal will go back to a solid state matching the mold inner cavity shape. It is possible to add cores or pins in order to realise and shape emply areas inside the part. The pouring can be made manually or automatically from the top of the mold. Mold is then open for the extraction of the part. It is important to notice that die dressing is added inside the tooling in order to facilitate part extraction.

Other A.G.C. BUSINESS CONSULTING S.A. products

Metal

Related Searches

- Anodic oxidation

- Aluminum anodic oxidation

- Anodic oxidation with coloring

- Painting

- Painting on metal

- Polishing

- Metal polishing

- Sand blasting

- Automotive anodic oxidation

- Industrial anodizing

- Aeronautic anodic oxidation

- Chrome plating

- Ferrous metals sand blasting

- Steel chrome plating

- Painting on steel

- Aluminum sand blasting

- Industrial painting

- Industrial polishing

- Aeronautic painting

- Aeronautic sand blasting

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.