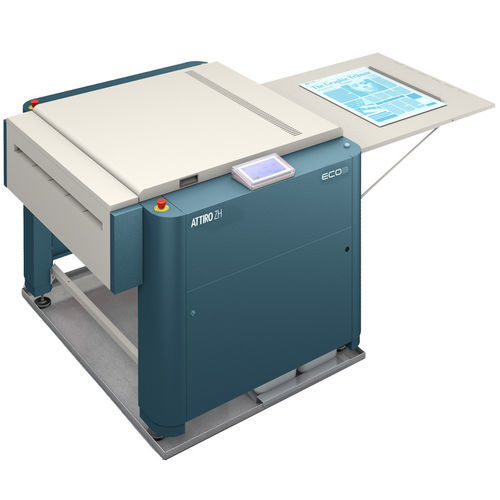

High-speed Offset plate cleaning machine Attiro ZHwith chemistry free cleaning

Add to favorites

Compare this product

Characteristics

- Other caracteristics

- high-speed, with chemistry free cleaning

- Plate width

Max.: 710 mm

(28 in)Min.: 200 mm

(8 in)- Plate length

275 mm

(11 in)- Throughput

400 p/h

Description

Meet Attiro ZH, the high-speed clean-out unit for your violet chemistry-free plates. Its groundbreaking cascade technology makes your operations both more productive and sustainable, as the concentrated gum is reused in three cascading sections. In this way, the non-imaged areas are effectively removed and there is no risk of oxidizing. The result: minimal gum consumption and little waste for a maximal clean-out effect. Full maintenance, with our dedicated circulation cleaner ATTIRO CareClean, is only required after 8,000 m².

The addition of the Attiro Cleaning Module (ACM) even extends the main cleaning cycle for Attiro COUs to 12,000 m² of plate consumption. Furthermore, the two intermediate cleaning processes at 4,000 and 8,000 m² are executed as part of an automated process that starts with a simple keystroke on the Attiro display and requires no further intervention from the operator.

The Attiro ZH clean-out unit forms a very attractive solution combined with the Avatar V-ZH preheat-free chemistry-free printing plate, and the Advantage N platesetters.

Reduce costs

- No preheat unit results in reduced CAPEX, up to 80% energy savings, more floor space, and no buckling of plates because of heating/cooling

- Minimal gum consumption for maximal clean-out effect; less transport of gum bottles

Easy to use

- Easy visual check and no mix-ups on press thanks to high-contrast image on the gummed plate

- Extensive bath life, with full maintenance only required after 8,000 m² (or 12,000 m² when the Attiro Cleaning Module is installed)

VIDEO

Catalogs

No catalogs are available for this product.

See all of ECO3‘s catalogsRelated Searches

- Plate processor

- Ctp plate

- Thermal plate processor

- Thermal offset plate

- Manual CtP

- Plate cleaning machine

- Negative working offset plate

- Automatic CtP

- Thermal plate CtP Processor Cleaner

- CtP with delivery table

- CtP with feed table

- Water CtP Processor Cleaner

- Positive working offset plate

- Internal drum CtP

- External drum CtP

- Violet offset plate

- High-speed CtP

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.