- Industrial machines and equipment

- Welding and Assembly

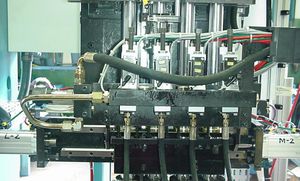

- Automatic assembly machine

- AGME Automated Assembly Solutions

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Automatic assembly machine for ball jointsgreasing

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Applications

- for ball joints

- Other characteristics

- greasing

Description

Assembly, rolling over and greasing of double head links, stabilizer bars

TECHNOLOGIES

Rotary transfer with 12 workstations

Fixture controlled components on a rotary plate

Design and manufacturing of special fixtures

Automatic feeding of components

Control by PLC

Automatic rolling over of housing

Automatic greasing of components by utilizing dosing technology

Components presence, torque and air seal control

Automated assembly of all of components

Automatic unloading of stabilizer bars with reject management

Built-in 180º turning to allow assembly of both sides of parts

ADVANTAGES

Integration of all stabilizer bars assembly, greasing and control processes in one single machine

Optimization of the assembly process that results in significant improvements in productivity

Assembly of both sides of the link by automatically rotating the link 180º just after completion of one side.

Air seal check during link assembly

Catalogs

No catalogs are available for this product.

See all of AGME Automated Assembly Solutions‘s catalogsOther AGME Automated Assembly Solutions products

SPECIAL MACHINES

Related Searches

- Welding system

- Automatic welding system

- Laser welding system

- Mounting machine

- Automatic mounting machine

- Electric welding system

- Assembly line

- AGME riveting machine

- Automated assembly line

- Screwing machine

- Automatic screwing machine

- AGME automatic riveting machine

- Electric riveting unit

- AGME pneumatic riveting machine

- AGME radial riveting machine

- Orbital riveting unit

- Control assembly line

- Bench-top riveting machine

- Clinching machine

- Pre-assembling machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.