Riveting, greasing and insertion of bushings in car seat recliners

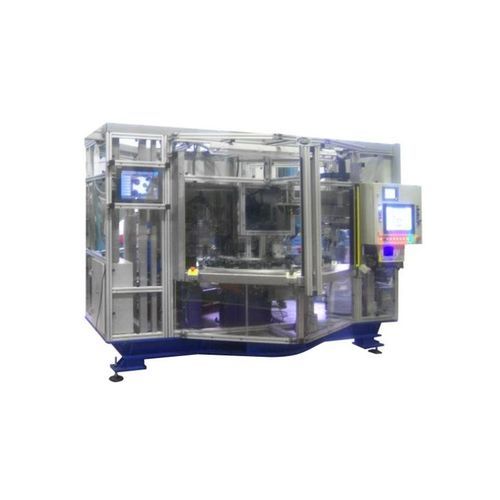

Machine that requires two operators

TECHNOLOGIES

Rotary transfer with 6 workstations

Palletized components on a rotary plate

Design and manufacturing of special fixtures placed on pallets

Parts presence detection by laser

Control by artificial vision

Riveting of 5 positions with 2 controlled axis

Bushings insertion by a pneumatic unit

Greasing with volumetric doser

“Num” numerical control

Automatic unloading of recliners with OK / NOK parts selection

ADVANTAGES

Integration of the recliners assembly, greasing and control processes in one only machine

Adaptation to the client automation requirements

Robust and compact machine that saves room in the factory

Flexible machine that is valid for different models

Artificial vision system that optimizes the parts control process