- Machine-tools

- Machining Center

- Rotary transfer machine

- AGME Automated Assembly Solutions

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

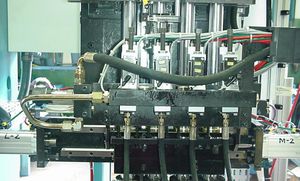

Rotary transfer machine CNC6-positionsemi-automatic

Add to favorites

Compare this product

Characteristics

- Type

- rotary

- Control type

- CNC

- Number of positions

- 6-position

- Other characteristics

- semi-automatic, assembly

Description

Latches assembly, greasing and effort control with 2 operators

Valid for right hand and left hand latches

TECHNOLOGIES

Dial transfer with 6 workstations

Design and manufacture of special tooling and fixtures

Components presence control by inductive sensors

Automatic insertion of bolts and bushings by pneumatic presses

Automatic greasing of bushings and claws by dosing system

Final assembly of parts by a hydraulic press

Control of the latch release and locking force

Control by automata

Quality assurance system

Automatic unloading of latches with OK / NOK parts selection

ADVANTAGES

Robust and compact semi-automatic machine that saves room in the site

Integration of all latch assembly, greasing and control processes in one single machine

Optimization of the production time

Customized flexible solution that is valid for both hands: right and left

Efficient and innovative system for controlling the release and locking force after the latch assembly

Process control that guarantees the final quality of the assemblies

Catalogs

No catalogs are available for this product.

See all of AGME Automated Assembly Solutions‘s catalogsOther AGME Automated Assembly Solutions products

SPECIAL MACHINES

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.