- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

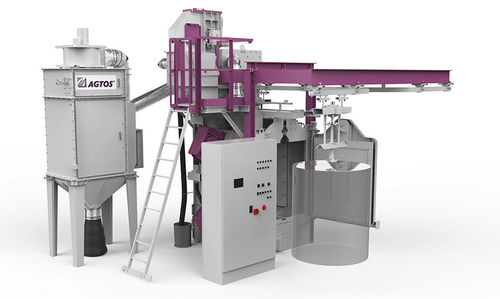

Overhead conveyor shot blasting machine HT seriesfor metalautomaticmultipurpose

Add to favorites

Compare this product

Characteristics

- Type

- overhead conveyor

- Applications

- for metal

- Other characteristics

- automatic, multipurpose

Description

Overhead conveyor blast machines are among the most flexible blast machine types. They are used for a variety of workpieces for derusting, descaling, final sanding, deburring and finish blasting of sensitive components or for roughening surfaces for subsequent coating.

They are generally offered as batch or continuous systems. However, there are numerous intermediate forms that are orientated towards the rail guidance of the suspension track system. In many cases, different machining processes such as blasting, painting and subsequent drying can be combined with each other using the overhead conveyor system, thereby exploiting enormous rationalisation potential.

Further variation possibilities arise through the use of different blasting racks with the help of which the workpieces are fed into the machine. In many cases, standard blasting frames with discs, baskets or bars can solve the task. However, the requirements of our customers are always clarified in detail and often lead to a customised solution.

Overhead conveyor blast machines Product programme

Our standard programme for overhead conveyor blast machines includes several sizes.

The determination of the suitable machine concept depends, among other things, on the workpieces, the required output and, last but not least, the customer's ideas regarding an optimised production process

The workpieces are suspended from a blasting frame or directly from the rotating hooks of the travelling gear and pushed to just in front of the steel machine. An automatic infeed device transports them to the first blasting position.

VIDEO

Catalogs

No catalogs are available for this product.

See all of AGTOS GmbH‘s catalogsRelated Searches

- AGTOS shot blasting machine

- AGTOS metal shot blasting machine

- AGTOS automatic shot blasting machine

- Continuous shot blasting machine

- Belt blast machine

- Turbine shot blasting machine

- Hook shot blasting machine

- Roller conveyor blast machine

- Rotating table shot blasting machine

- Bulk material shot blasting machine

- Rotary drum blast machine

- Concrete shot blasting machine

- Tube shot blasting machine

- Multipurpose shot blasting machine

- Pipe shot blasting machine

- Sheet metal shot blasting machine

- Shot peening machine

- Metal shot peening machine

- Semi-automatic shot blasting machine

- Rotating table shot peening machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.