Chamber furnace conveyorquenchingcontinuous

Add to favorites

Compare this product

Characteristics

- Configuration

- chamber, conveyor

- Function

- quenching

- Other characteristics

- continuous

Description

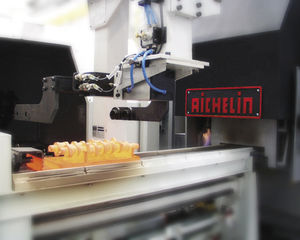

STEP-CHAIN CONVEYOR FURNACE

THE INNOVATIVE

Hot forming of car body parts in the automotive industry sets new standards for component properties in series production. Complex components can be produced economically with high stability and optimized formability at will.

The heatXpress press hardening furnace impresses with highest flexibility, precision and availability and is the optimal solution with its unique transport system for press hardening of blanks, pipes & other pre-formed profiles. Translated with www.DeepL.com/Translator

ADVANTAGES:

Short conveying times from the furnace into the press, selectable cooling times down to a minimum time of 4.2 seconds.

High positioning precision of the drive system. The goods carriers are positioned in front of the press with a precision of +/- 1 mm.

The drive system is suitable for direct manufacturing (blanks directly on the transport system) as well as for indirect manufacturing (blanks on goods carriers).

The distances between the goods carriers inside the furnace can be kept at a minimum, the furnace is thus shorter than usual roller hearth furnace.

No roller cracks caused by intrusion of the lamination material of the blanks.

No reversing of the furnace drive in case of production standstills and power blackouts.

Longer maintenance intervals for the furnace doors (due to the execution with 2 parallel heating chambers)

PROCESSES

Press Hardening

Hardening

COMPONENTS:

Blanks

Various Steel Components

Catalogs

No catalogs are available for this product.

See all of Aichelin Group‘s catalogsRelated Searches

- Furnace

- Chamber furnace

- Electric furnace

- Heat treatment furnace

- Combustion furnace

- Gas furnace

- Tunnel furnace

- Industrial furnace

- Automatic furnace

- Annealing furnace

- Continuous furnace

- Quenching furnace

- Compact furnace

- Conveyor furnace

- Tempering furnace

- Aging furnace

- Muffle furnace

- Hardening furnace

- Rotary furnace

- Preheating furnace

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.