Conveyor furnace rollerheat treatmentgas

Add to favorites

Compare this product

Characteristics

- Configuration

- conveyor, roller

- Function

- heat treatment

- Heat source

- gas

- Other characteristics

- continuous, compact

Description

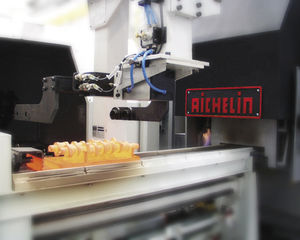

CAST PLATE BELT FURNACE

AICHELIN cast plate belt furnaces are primarily used for the heat treatment of small bulk parts, especially for tempering hot-forged parts under protective gas.

PROCESSES

Hardening & Tempering

Carburizing

Carbonitriding

Annealing under protective gas

Bainitisation

COMPONENTS

Screws and other fastening elements

Automotive safety components

Chain elements

Roller bearing components

Standard parts

CAPACITY

750 – 3000 kg/h quenching and tempering capacity

For small capacities we recommend the use of SAFED cast link belt furnaces.

CHARACTERISTICS (COMPARED TO CAST LINK BELTS)

Conveyor belt completely guided in the furnace, thus highest thermal energy efficiency

Use of roller-supported cast link belts enables up to 10 times longer belt life

Compact furnace design due to the possibility of double belt loading when using solid cast link belts

Components with an operating weight of 0.01 to 2 kg each and a max. length of 400 mm

Catalogs

No catalogs are available for this product.

See all of Aichelin Group‘s catalogsRelated Searches

- Furnace

- Chamber furnace

- Electric furnace

- Heat treatment furnace

- Combustion furnace

- Gas furnace

- Tunnel furnace

- Industrial furnace

- Automatic furnace

- Annealing furnace

- Continuous furnace

- Quenching furnace

- Compact furnace

- Conveyor furnace

- Tempering furnace

- Aging furnace

- Muffle furnace

- Hardening furnace

- Rotary furnace

- Preheating furnace

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.