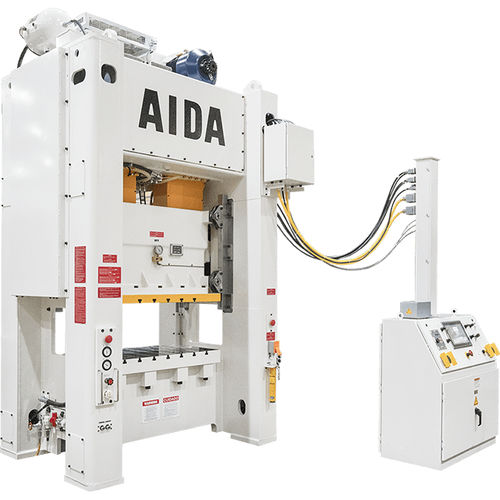

Mechanical press NSX-1100(1)stampingframeroller

Add to favorites

Compare this product

Characteristics

- Operation

- mechanical

- Function

- stamping

- Structure

- frame, roller

- Applications

- high-volume

- Force

1,100 kN

- Opening

400 mm, 500 mm

(16 in, 20 in)- Rate (strokes/min)

Max.: 300 p/min

Min.: 120 p/min

- Stroke

65 mm

(2.559 in)- Weight

17,000 kg

(37,479 lb)

Description

Low deflection, rigid unitized steel frame

Cast iron slide with detachable face

Inboard mounted carbon fiber counterbalances

Oversized ball type connection points

Recirculating oil lubrication system

65mm stroke length

50 inch L-R bed size

Floor mounted design for quick, pit-free installation

Allen-Bradley control standard with Link & Wintriss controls optional

Locally engineered at AIDA-America in Dayton, OH, the newly designed NSX meets the demands of high-volume stamping operations, with speeds ranging from 120 to 300 strokes per minute.

The automotive, appliance, hardware, and consumer goods industries, and all industries who depend upon consistent high-volume production, will benefit from the NSX.

A zero clearance, lubrication free, eight-point roller slide guide system and dual counter-rotating eccentric shafts ensure accuracy. AIDA's metal seal type Hydraulic Overload Protection (HOLP), the fastest acting HOLP in the industry, protects press and die integrity.

High-Volume Production Press Features

Dual Counter-Rotating Eccentric Shafts

Main Gears

Inboard Mounted Carbon Fiber Counterbalances

Extended Slide Adjustment for Quick Die Access

Oversized Ball Type Suspension Points

Fastest acting HOLP in the industry (10 ms)AIDA Hydraulic Overload Protection System (HOLP)

Quill Mounted FlywheelAIDA Wet Type Clutch and Brake

Plug-and-Play Control Junction Box

Roller GuidesRoller Guides

Cast Iron Slide with Detachable Slide Face

Rigid Unitized Steel Frame

Catalogs

No catalogs are available for this product.

See all of Aida S.r.l.‘s catalogsRelated Searches

- Aida Group industrial press

- Aida Group forming press

- Aida Group hydraulic press

- Automatic press

- Electric press

- Vertical press

- Pneumatic press

- Cutting press

- Aida Group stamping press

- Aida Group frame press

- Aida Group mechanical press

- PLC-controlled press

- Bending press

- Cambering press

- Press for the automotive industry

- C-frame press

- Compression press

- Sheet metal press

- Compact press

- Custom press

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.