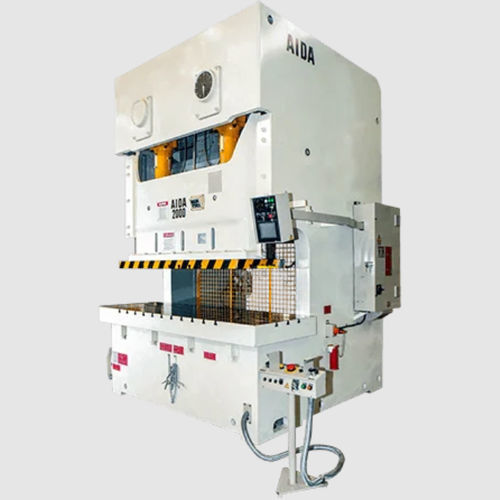

Mechanical press NC2 seriesstampingC-framevertical

Add to favorites

Compare this product

Characteristics

- Operation

- mechanical

- Function

- stamping

- Structure

- C-frame

- Other characteristics

- vertical

- Force

1,100 kN, 1,600 kN, 2,000 kN, 2,500 kN

- Opening

350 mm, 400 mm, 450 mm, 500 mm, 550 mm

(14 in, 16 in, 18 in, 20 in, 22 in)- Stroke

Max.: 280 mm

(11.024 in)Min.: 110 mm

(4.331 in)

Description

HIGH QUALITY, INDUSTRY LEADING MECHANICAL GAP FRAME PRESSES

Highly rigid frame with low angular deflection

Fast acting HOLP system (10 msec)

AIDA Wet clutch and Brake

6-Point full length Bronze Gibs

Brake stop-time monitoring display

Automatic lubrication system for Gibs and Crankshaft Bearings

AIDA MPC/SVC safety controller

Quill mounted flywheel with a flywheel brake

AC variable frequency drive

AIDA NC2 gap frame mechanical presses (also known as C frame mechanical presses) are available from 110 through 250 tons capacity. A compact rigid frame design minimizes the deflection rating and the low overall clearance minimizes reverse tonnage. The six-point slide guide system provides a long useful life. The wet-type clutch and brake provide higher intermittent rates and long life - important factors for hand-fed and top-stop applications.

An AC Variable frequency drive allows for wider speed ranges. The Quill mounted flywheel results in a larger bearing surface. The front to back mounted forged steel crankshaft along with hardened and precision ground gears are well suited for high stress blanking applications. Micro-Inching provides die setting at very low speeds. Additionally, an extensive spare parts inventory in Dayton, OH ensures continuous product support.

With over 3,000 AIDA mechanical gap frame presses installed in North America, it is easy to see that AIDA NC presses are an industry standard.

PRESS FEATURES

Highly rigid frame to minimize deflection

Ball and Socket Connections

Hydraulic Overload Protection System (HOLP)

AIDA Wet Clutch and Brake

Hardened & ground pinion and ground main gear

Quill Mounted Flywheel

Catalogs

No catalogs are available for this product.

See all of Aida S.r.l.‘s catalogsRelated Searches

- Aida Group industrial press

- Aida Group hydraulic press

- Aida Group forming press

- Automatic press

- Electric press

- Vertical press

- Cutting press

- Pneumatic press

- Aida Group stamping press

- Aida Group mechanical press

- PLC-controlled press

- Aida Group frame press

- Bending press

- Press for the automotive industry

- Cambering press

- C-frame press

- Compression press

- Sheet metal press

- Custom press

- Compact press

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.