- Hydraulics - Pneumatics

- Valve

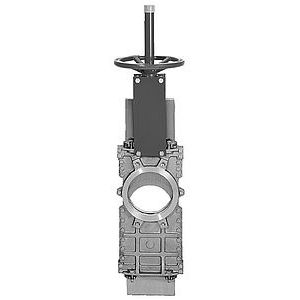

- Knife gate valve

- AKO ARMATUREN

- Products

- Catalogs

- News & Trends

- Exhibitions

Knife gate valve Cmanualelectrically-actuatedpneumatically-operated

Add to favorites

Compare this product

Characteristics

- Type

- knife gate

- Operation

- manual, electrically-actuated, pneumatically-operated

- Function

- for control

- Media

- for liquid food products and beverages

- Body

- with flange, monoblock, stainless steel, cast iron

- Applications

- for the chemical industry, for the food industry, process, for bulk materials, for powders, solids

- Other characteristics

- standard, unidirectional

- DN

Max.: 600 mm

(23.622 in)Min.: 50 mm

(1.969 in)- Pressure

Max.: 10 bar

(145 psi)Min.: 1 bar

(14.5 psi)

Description

The type C Knife Gate Valve for bulk material is a unidirectional wafer valve which was designed especially for bulk material technology (powder or granulated materials). The Knife Gate Valve AKO type C is primarily used in the

chemical industries

mining industries

food/beverage industries

agriculture and

animal feed sector

The nominal widths available for bulk material range from DN50 to DN600 with flange connections complying with EN 1092 PN10 or alternatively, ANSI B16.5 (class 150).

Design features of Knife Gate Valve type C

The structure of the uni-directional Knife Gate Valves for bulk material encompasses a so-called wafer style cast monoblock body, with raised face and reinforced ribs for larger nominal diameters for extra body strength.

Moulded guide ribs ensure the slide plate motion and closing mechanism.

The great installation length of the monoblock body and the standard rinsing connections prevent material build-ups in the body. The rinsing connections serve to clean the cavities within the monoblock body.

The rinsing process can be undertaken with air, steam or various liquids.

The monoblock body is available in either grey cast iron (GG25) or alternatively in stainless steel AISI 1.4408 (CF8M).

The slide plate is manufactured using stainless steel AISI 304 or AISI 316 as standard.

The plate radius of the slide gate has a bevelled cutting edge. As a result, solids can be cut through and a tight seal can be achieved in the closed position. On request the thickness of the Knife Gate Valve for bulk materials plate can be increased for higher operating pressures and/or higher quality material can be used.

Catalogs

Related Searches

- Valve

- Hand valve

- Control valve

- Stainless steel valve

- Water valve

- Pneumatic valve

- Threaded valve

- Valve with flange

- Regulating valve

- Stop valve

- Lever control valve

- Electric valve

- Valve with handwheel

- Pneumatically-operated valve

- Wedge gate valve

- Valve for the chemical industry

- Standard valve

- DIN valve

- ANSI valve

- Cast valve

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.