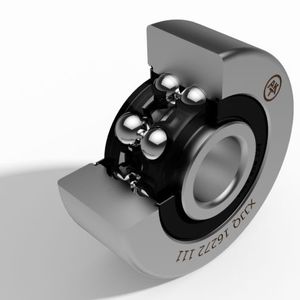

High-temperature bearing rollersteelautomotive

Add to favorites

Compare this product

Characteristics

- Rolling element

- roller

- Material

- steel

- Applications

- automotive

- Other characteristics

- sealed, high-temperature, with lubricant, custom

Description

High-temperature applications

High temperatures occur in customer applications placing particularly high demands on the structure of our roller bearings and track rollers. Therefor special design features must be taken into account. For example the selection of suitable high temperature materials chosen for seals and cages. The selection of the application's suitable lubricant greatly depends on the temperature range and the product's requirements. Fundamentally our roller bearings and track rollers, designed for high temperature applications, are divided into products which are lubricated with high temperature greases or solid lubricants.

High temperature roller bearings/ track rollers -- lubricated with grease

suitable for high temperature applications up to 250°C

suitable for low rotational speeds

optional design with compatibility for automotive painting facilities

life-long lubrication design is possible

optional lubricant for contact with food (NSF H1)

custom configuration with re-lubrication features

basic configuration with frictionless steel seals

custom-made configuration fitted with contact seals up to 200°C

High temperature roller bearings/ track rollers -- solid lubricant

suitable for high temperature applications up to 350°C

suitable for low rotational speeds

lifelong lubrication design

graphite molybdenum disulphide based lubricant

running-in characteristics optimized using special surface coating

basic configuration with frictionless steel seals

custom-made configuration fitted with contact seals up to 200°C

Catalogs

No catalogs are available for this product.

See all of AKT GmbH‘s catalogsRelated Searches

- Rolling bearing

- Steel bearing

- Ball bearing bearing

- Roller bearing

- Radial rolling bearing

- Single-row bearing

- Deep groove ball bearing

- Double-row bearing

- Cage assembly bearing

- Industry bearing

- Metal shaft

- Sealed bearing

- Automotive bearing

- Heavy load bearing

- High-performance bearing

- Thrust bearings

- Combined bearing

- Needle roller bearing

- Plastic bearing

- Transmission bearing

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.