Conveyor roller

Add to favorites

Compare this product

Description

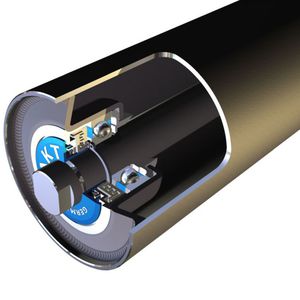

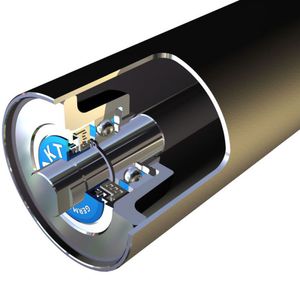

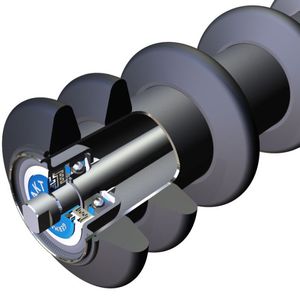

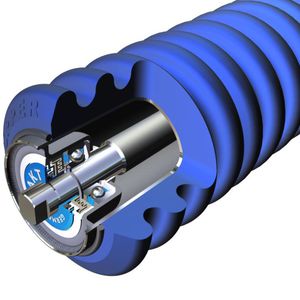

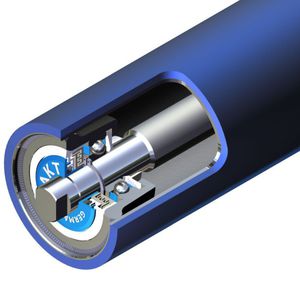

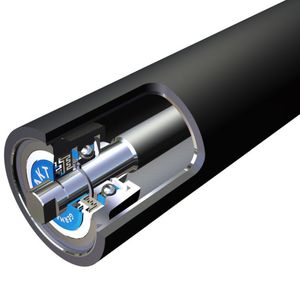

Impact Rollers Premium

Characteristics:

Idler tube machine-turned, surface roughness Ra=12.5 μm, made of longitudinal seam-welded steel tubes acc. to EN 10305-3 with restricted tolerances (Küpper Standard), S235JR acc. to EN 10025-2

Bearing housings forged from C15 acc. to EN 10267-2 or S235JR acc. to EN 10025-2

Bearing housings with seat IT7 acc. to EN ISO 286-1

Axles made of round bar steel acc. to EN 10083-2 or bending-resistant hollow axle, precision tube with welded shaft extensions; seat IT6 acc. to EN ISO 286-1

Deep-groove ball bearings AKT, FAG, or SKF acc. to DIN 625-1 2Z, plastic cage, greased for life; lubrication designed to customer specifications

Deep-groove ball bearing sizes 6310 – 6318

Deep-groove ball bearings – ISO tolerance class 5 (P5) acc. to DIN 620-2

Radial internal clearance of the deep-groove ball bearings C4H acc. to DIN 620-4

Self-aligning roller bearings AKT, FAG, or SKF acc. to DIN 635-1, with steel sheet cage or brass cage, greased for life; lubrication designed to customer specifications; bearings sealed

Self-aligning roller bearings sizes 21312 - 22318

Self-aligning roller bearings – ISO tolerance class 0 (P0) acc. to DIN 620-2

Radial internal clearance of the self-aligning roller bearings C3 acc. to DIN 620-4

Additional inner sealing made of high-quality materials

Patented QLR Hybrid Sealing, greased for life, especially effective against the intrusion of water and dust

Additional protection against extreme conditions by use of a solid protection cover

True running ≤ 0.2 mm/m (average of the total delivery)

Catalogs

No catalogs are available for this product.

See all of AKT GmbH‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.