- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

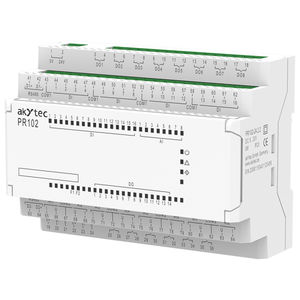

DIN rail PLC PR103 8-Oanalog inputsdigital input

Add to favorites

Compare this product

Characteristics

- Type

- DIN rail

- Input/output

- digital input, analog inputs, digital outputs, analog outputs, 8-O

- Network

- RS485, Modbus RTU, Modbus TCP, Ethernet

- Other characteristics

- built-in

Description

PR103 is a Mini-PLC with extended communication capabilities thanks to its Ethernet port and two RS485 interfaces as well as both Modbus TCP and Modbus RTU/ASCII protocols. While communicating via Modbus RTU/ASCII over the RS485 interfaces on the field/control level, PR103 can use the Ethernet port and Modbus TCP to ‘bridge’ data to the supervisory level of the automation pyramid.

The PR103 Mini-PLC is equipped with 10 digital inputs, 8 digital outputs, 6 analog inputs, and 2 analog outputs. Moreover, 4 of 10 digital inputs can be used as pulse counters processing signals from 100-kHz encoders. Concerning the analog inputs, they are configurable and can operate with a wide range of RTDs, NTC/PTC, as well as with standard linear signals of 4-20 mA or 0-10 V. Furthermore, the built-in I/Os may be directly expanded with up to two extension modules of the PRM series.

Thanks to built-in flash memory, the logging of, e.g. values on analog inputs/outputs, pulse counters, device status, etc., is possible. The file is stored in the CSV format, which allows its running in almost any spreadsheet editor, for example, Excel.

Designed for installation on a DIN rail in a control cabinet, PR103 can operate in non-heated environments down to -40°C as well as in heated ones in temperatures up to +55°C.

A user program is written in function block diagram language in the akYtec ALP programming software, which is available free of charge. The control algorithm is loaded into the device memory via a micro USB cable connection.

Functions and features

Ethernet port (Modbus TCP, Client/Server)

2x RS485 interfaces (Modbus RTU/ASCII, Master/Slave)

Catalogs

PRODUCT OVERVIEW 2024

64 Pages

Related Searches

- Display module

- Industrial display module

- AkYtec digital I/O

- I O module

- Analog master module

- Digital I O module

- LED display module

- Digital panel meter

- Digital temperature control

- Temperature controller

- Color display module

- Panel-mount panel meter

- Control display module

- Fieldbus I O module

- Programmable logic controller

- Digital temperature control unit

- Serial I/O

- AkYtec remote I/O

- PID temperature control

- DIN rail I O module

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.