- Packing - Handling - Logistics

- Packing and Packaging

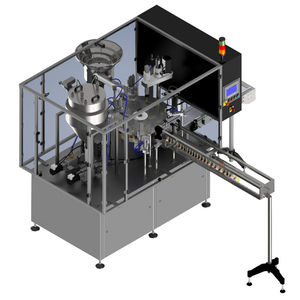

- Fully-automatic filler-sealer

- Albertina Machinery spol. s.r.o.

Fully-automatic filler-sealer PHARMLINEliquidsfor cosmetic productsfor the pharmaceutical industry

Add to favorites

Compare this product

Characteristics

- Operational mode

- fully-automatic

- Product applications

- liquids, for cosmetic products, for the pharmaceutical industry

- Throughput

Min.: 500 p/h

Max.: 2,400 p/h

Description

Pharmline – Filling and capping monoblocks

Filling and capping monoblocks are used to fill up ampoules, bottles and jars and to seal them with screw, pressure and twist-off caps. The system can also apply caps for lyophilisation and subsequent crimping.

Filling and capping monoblocks are used mainly in the pharma and cosmetic industry. They have a place also in food factories with limited space to accommodate a filling line with independent filling and capping machine. The monoblocks are used mainly to fill up smaller volumes.

The filling and capping monoblocks are produced in two versions: Pharmline 1 with a capacity of up to 2,600 bottles (ampoules) per hour and Pharmline 2 with a capacity up to 5,200 bottles (ampoules) per hour.

Pharmaceutical factories use mainly peristaltic pumps, less often flow sensors for dosing; while Lobe pumps are used in the food industry and gear pumps especially in the cosmetic industry.

Vibration feeders are used mainly to supply caps, less often rotation feeder.

The capping head is powered by a servomotor with exact closing torque that can be set on the control panel.

Pharma monoblocks are produced in accordance with the requirements of GMP and FDA. Validation documents and the complex installation, operational and process qualifications are part of the delivery.

VIDEO

Other Albertina Machinery spol. s.r.o. products

Monoblocks for filling and capping of bottles, pouches, buckets

Related Searches

- Automatic filler

- Liquid filler

- Filler for the food industry

- Bottle filler

- Bottle labeling machine

- Volumetric filler

- Semi-automatic filler

- Filling system for the chemical industry

- Filler for the pharmaceutical industry

- Filler for the cosmetics industry

- Checkweigher

- Piston filler

- Automatic capper

- Wrap-around labelling machine

- Bottle capper

- Filling and capping machine

- Linear filler

- Automatic filler and capper

- Filler and capper

- Filling and sealing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.