- Packing - Handling - Logistics

- Packing and Packaging

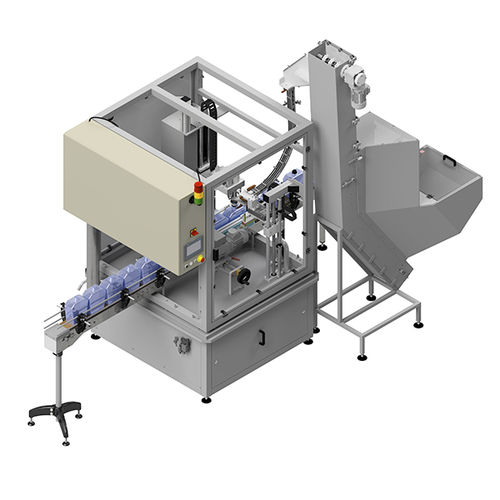

- Linear capping machine

- Albertina Machinery spol. s.r.o.

Linear capping machine CAPLINE CNautomaticcansbottle

Add to favorites

Compare this product

Characteristics

- Type

- linear

- Operating mode

- automatic

- Product applications

- cans, bottle

- Throughput

Min.: 1,500 p/min

Max.: 3,000 p/min

Description

Automatic linear capping machines

CAPLINE CN - Capping machine with stationary capping head

This is the basic version of automatic single-headed capping machines. The bottles and canisters are stopped under the capping head with the help of sidebands. The caps are aligned using a band feeder or a rotation aligner and transported on a conveyor to a pick-and-place station, which passes the cap under the capping head. The capping head is set on the cap and tightens it to the required screw torque. The capacity of the machine is 1,500 bottles per hour.

CAPLINE Dynamic with movable capping head

The containers (bottles and canisters) do not stop but the capping head moves during sealing together with the container. This way, spilling of the filled product is eliminated, which is of special importance mainly in case of a larger capacity. The head is moved on the x and y axes by servomotors. The screw torque is also operated by a servomotor. The capacity of a single-headed machine is up to 3,000 containers per hour.

VIDEO

Other Albertina Machinery spol. s.r.o. products

Capping machines

Related Searches

- Automatic filler

- Liquid filler

- Filler for the food industry

- Bottle filler

- Bottle labeling machine

- Volumetric filler

- Semi-automatic filler

- Filling system for the chemical industry

- Filler for the pharmaceutical industry

- Filler for the cosmetics industry

- Checkweigher

- Piston filler

- Automatic capper

- Wrap-around labelling machine

- Bottle capper

- Filling and capping machine

- Linear filler

- Automatic filler and capper

- Filler and capper

- Filling and sealing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.