- Packing - Handling - Logistics

- Packing and Packaging

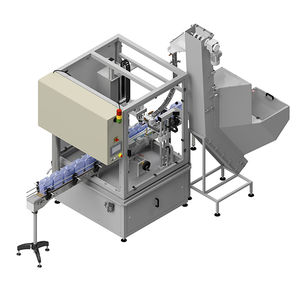

- Pressure capping machine

- Albertina Machinery spol. s.r.o.

Rotary capping machine Capline ROTpressuremulti-headautomatic

Add to favorites

Compare this product

Characteristics

- Type

- rotary, pressure, multi-head

- Operating mode

- automatic

- Product applications

- for twist-off caps, bottle

Description

Automatic rotary capping machine

Capline ROT 1 - Single head capping machine

Rotary capping machines are intended for capping various types of containers with screw, pressure and twist-off caps.

Rotary machines are mainly used to close smaller containers and for the closing of special caps (for example, caps with shallow threads). The containers are moved from the conveyor to a step-by-step carusel table, then under the capping head, where the cap is placed using a pick-and-place mechanism into the capping head. Then the container is closed.

The maximum capacity of the single-headed machine is 2,600 bottles/hour.

Capline ROT MULTIHEAD - Multi-head capping machines

Continual multi-headed rotary machines are used if larger amounts of bottles are to be closed. Three-heads machines have a capacity of 4,000 bottles per hour, four heads for 6,000 bottles per hour. After separation of the bottles by timming screw entry, the bottles are passed into the entry carousel and led to the central carousel, where the bottles are being capped while moving. The capping heads are moved together with the closed bottle. After capping, the bottles are transported by an exit carousel to the exit conveyor.

VIDEO

Other Albertina Machinery spol. s.r.o. products

Capping machines

Related Searches

- Automatic filler

- Liquid filler

- Filler for the food industry

- Bottle filler

- Bottle labeling machine

- Volumetric filler

- Semi-automatic filler

- Filling system for the chemical industry

- Filler for the pharmaceutical industry

- Filler for the cosmetics industry

- Checkweigher

- Piston filler

- Automatic capper

- Wrap-around labelling machine

- Bottle capper

- Filling and capping machine

- Linear filler

- Automatic filler and capper

- Filler and capper

- Filling and sealing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.