Foam core sandwich panel polystyrene foam corePVC foam corepolyurethane core

Add to favorites

Compare this product

Characteristics

- Core

- foam core, polystyrene foam core, PVC foam core, polyurethane core, rock wool core, glass wool core, mineral wool core, extruded polystyrene core, corrugated aluminum core

- Facing

- aluminum facing, with stainless steel facing

- Applications

- for ceiling, for wall, for partition wall, for laboratories

- Other characteristics

- acoustic, sound-absorbing, fire-resistant, modular, waterproof, corrosion-resistant

- Thickness

60 mm

(2.362 in)

Description

Walls, partition panels

Current laboratories are areas subject to rapid evolution. Their departments undergo reorganisations requiring a new use of the available space. This has made the use of panels for clean rooms the best system for compartmentalising, replacing traditional partitions.

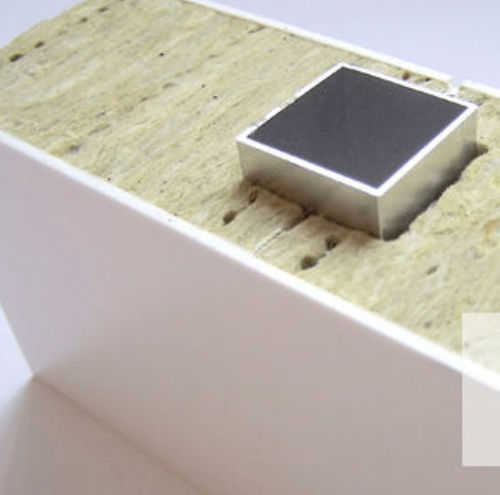

SANDWICH PANEL

The division of new departments or the modification of existing ones can be carried out quickly and at minimal cost. The partitions assembly consists of self-supporting monolithic panels of various thicknesses, connected with hidden aluminium profiles. Made of sandwich panel, they have a smooth surface and are easily disassembled.

We have wide range of panel types to meet the specific needs of each project. The particular concept of the system for building and assembling movable walls allows a single panel to be replaced without the need to remove its adjoining panels. The panels’ standard thickness is 60 mm which allows the embedding of the electrical fittings – switches, sockets, pushbuttons, door state signalling lights, etc – as well as the building of removable and inspectable technical panels (utilities).

The movable walls are made of modular self-supporting panels with surface finishes suitable for providing sterile and controlled contamination ambients.

The choice of coating depends on the activity undertaken in the clean room. The following surface finishes are available for walls:

• Laminated melamine on compact phenol.

• Lacquered aluminium.

• Enamelled sheet.

• Stainless steel.

• Glass.

Related Searches

- LED lighting

- Profile

- Metal profile

- Metal door

- Light fitting lighting

- Aluminum profile

- Security door

- IP65 lighting

- High-speed door

- Aluminum door system

- Stainless steel door system

- Polycarbonate lighting

- Sandwich panel

- Fluorescent lighting

- T-slot profile

- Office lighting

- Hinged door

- Extruded profile

- IP20 lighting

- Hermetically-sealed door system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.