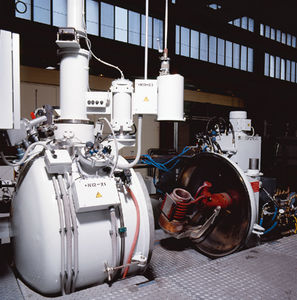

Bell oven VIMmeltinginductionvacuum

Add to favorites

Compare this product

Characteristics

- Configuration

- bell

- Function

- melting

- Heat source

- induction

- Atmosphere

- vacuum

Description

ALD Vacuum Technology GmbH designs, engineers and manufactures a variety of small vacuum induction melting & casting systems used to produce high-quality metal alloys for R&D and pilot scale production. ALD has extensive experience in combining various melting technologies with casting systems to address specific material requirements and to produce alloys with different geometries. ALD’s history as a VIM technology leader includes experience in delivering small scale VIM systems to leading R&D institutes and specialty metal alloy producers throughout the world.

The application-specific combination of melting sub-systems combined with different casting techniques enables production of a wide range of super-clean metal alloys, including super-alloys, precious metals, refractory and reactive metal alloys. Our clients can choose between small VIM systems with charge weights from 1 kg up to 750 kg. ALD can customize systems using its library of design variations to meet customer requirements.

Related Searches

- Furnace

- Chamber furnace

- Electric furnace

- Heat treatment furnace

- Laboratory furnace

- Combustion furnace

- Gas furnace

- Tunnel furnace

- Vacuum furnace

- Annealing furnace

- Melting furnace

- Sintering furnace

- Quenching furnace

- Conveyor furnace

- Tempering furnace

- Tubular furnace

- Induction furnace

- Bell furnace

- Rotary retort furnace

- High-vacuum furnace

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.