- Machine-tools

- Finishing Machine

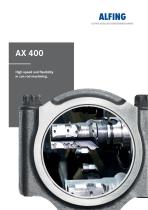

- Boring finishing machine

- Alfing Kessler Sondermaschinen GmbH

Machining finishing machine AF 400boringmulti-spindlehigh-speed

Add to favorites

Compare this product

Characteristics

- Associated function

- boring, machining

- Other characteristics

- high-speed, multi-spindle

Description

PRECISION AND FLEXIBILITY IN CON ROD MACHINING

UNCOMPROMISINGLY SPECIALIZED

The AT 200 and the AF 400 con rod machines are specialized in semi-finish and finish machining whereby every machine is optimally designed for the corresponding requirements. Highly precise sub-assemblies are only used where required.

THE AF 400 MACHINE FOR FINISH MACHINING OF CON RODS

Highest precision due to optimized servo axis arrangement

No protruding masses thanks to compact axis arrangement

Oval and trumpet form bores with freely programmable geometry

Simple, scalable production increase

Hydrostatic spindles with highest precision, stiffness and dampening

Optional with more cost-efficient spindles with roller bearings

Up to 4 fixture plates can be mounted for short change-over times

Directly driven, NC-programmable main spindles

High thermal stability

High ease of operation

Very good accessibility for maintenance and tool change

Low space requirements on floor and in height

CLAMPING FIXTURE

UNCOMPROMISINGLY FLEXIBLE

The clamping fixture swivels around the A-axis and can be moved linearly in Y-direction. It can be quickly changed over and allows a clamping sequence freely programmable in the NC program. Due to the high flexibility, it offers the possibility to quickly, easily and cost-efficiently produce different work pieces on the machine. Thanks to the four-sided tombstone concept, up to 4 different component types can be machined without any change-over.

UNCOMPROMISINGLY PRECISE

All main spindles of the AF 400 are equipped with hydrostatic bearings and direct drives, preventing vibration problems occurring with usual belt drives.

Other Alfing Kessler Sondermaschinen GmbH products

CON ROD MACHINING

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.