- Metrology - Laboratory

- Optical Component

- Dielectric mirror

- Alien Photonics

- Products

- Catalogs

- News & Trends

- Exhibitions

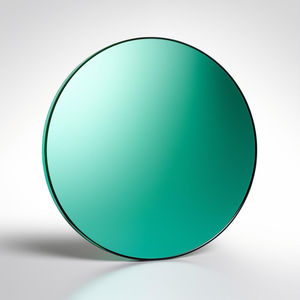

Dielectric mirror roundNd:YAG laserhigh-reflectivity

Add to favorites

Compare this product

Characteristics

- Type

- dielectric

- Shape

- round

- Use

- Nd:YAG laser

- Options and accessories

- high-reflectivity

Description

Nd:YAG Laser Line (HR) Mirrors are designed for fundamental (1064 nm) or harmonic (532, 355, 266 nm) Nd:YAG laser beam steering. Custom material, size, shape and other parameters available.

What is Nd:YAG Laser Line (HR) Mirror?

Nd:YAG Laser Line (HR) Mirror is an optical component coated with dielectric thin-film coating stack. This mirror is specifically designed to reflect Nd:YAG laser harmonics. Unlike output couplers (partial reflectors), these mirrors are designed and manufactured in such way to achieve maximal possible reflection value, instead of specific reflection value.

How Nd:YAG Laser Line (HR) Mirrors are produced?

Similarly to Yb:YAG and Ti:Sapphire Laser Line MIrrors, Alien Photonics Nd:YAG Laser Line (HR) Mirrors' production begins with optical substrate preparation – polishing and inspecting them. The next step is coating design – these mirrors are optimized for specific Nd:YAG laser line (single band, narrow band) and the design goal is to either make the best possible reflection (HR) or produce mirrors with high laser induced damage threshold (LIDT). Based on the priority, specific coating materials are chosen. Coating also can be optimized for specific angle of incidence (AOI). Most popular AOI’s are 0°, 45° or 56°. Alien Photonics also offers custom angle of incidence optimizations: 5°, 8°, 12, 22.5°, etc. If you'd like your mirror to work at several incidence angles? No problem, just let us know the range.

How to handle and clean Nd:YAG Laser Line (HR) Mirrors?

Dielectric coated Nd:YAG Laser Line (HR) Mirrors are way more resistant to physical contact and environmental impact when comparing to bare metal coated mirrors (Au, Ag, Al).

Related Searches

- Glass lens element

- Optical prism

- Spectrum lens element

- Optical window

- Optical lens element

- Glass optical prism

- Visible lens element

- Round mirror

- BK7 lens element

- Convex array lens element

- Laser lens element

- Crystal lens element

- Silica lens element

- Spherical lens element

- Round optical window

- UV lens element

- Fused silica lens element

- Laser mirror

- Cylindrical lens element

- Plano-convex lens element

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.