- Metrology - Laboratory

- Optical Component

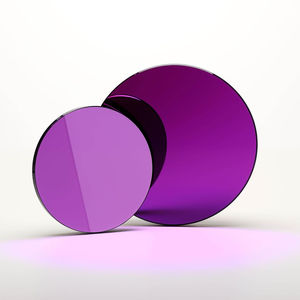

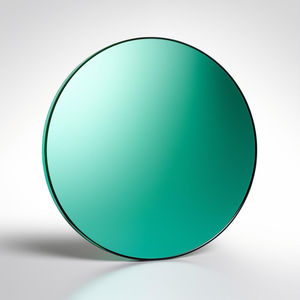

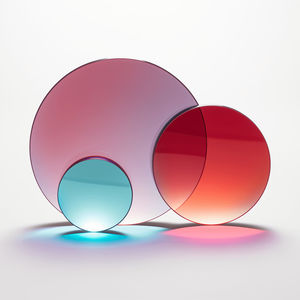

- Flat mirror

- Alien Photonics

- Products

- Catalogs

- News & Trends

- Exhibitions

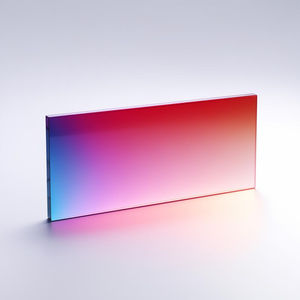

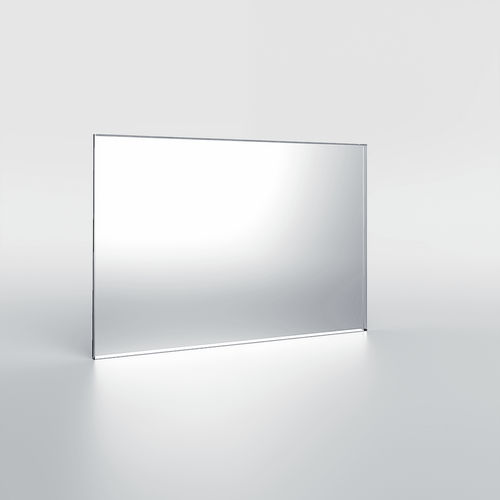

Flat mirror rectangularscanninglaser

Add to favorites

Compare this product

Characteristics

- Shape

- flat, rectangular

- Use

- laser, scanning, beamsplitter

- Options and accessories

- output coupling

Description

NPBS Plate’s main function is to separate laser beam at specific ratio, into two beams, while preserving polarization state.

What is NPBS plate?

Non-Polarizing Beam Splitter (NPBS) Plate is an advanced optical component designed to split incoming laser beam into two, based on designed split ratio and without altering polarization state.

NPBS plate alternatives

NPBS plate function is the same as NPBS cube. Usually, with very small effort these components can be interchangeable. NPBS plate splits beam according to designed split ratio, similarly to output couplers (partial reflectors), but also keeps polarization state intact.

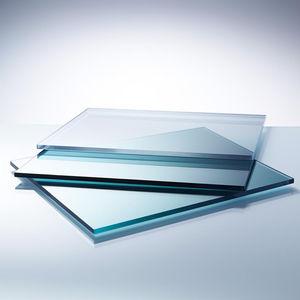

How NPBS plates are made?

NPBS plates are fabricated using high-quality optical substrates. The surfaces are meticulously polished to ensure high surface quality and flatness. Non-polarizing beamsplitter coating is applied to achieve desired split ratio. Backside of plate is then (optionally) coated with anti-reflection coating to reduce back reflection (ghost reflections). Once finished, Alien Photonics NPBS plates are inspected and shipped to customer or stored in special optics boxes.

NPBS plates for compact imaging systems

NPBS thin, plate-like design makes them preferable over NPBS cubes in space-constrained optical setups. In these devices (mini cameras, microscopes), Alien Photonics NPBS plates help to maintain uniform illumination without bulkiness of cube.

NPBS plates for ultrafast lasers

NPBS plate has an ability to split or combine broad bandwidths of high intensity laser pulses without introducing large dispersion or polarization dependent loss.

Related Searches

- Glass lens element

- Optical prism

- Spectrum lens element

- Optical window

- Optical lens element

- Glass optical prism

- Visible lens element

- Round mirror

- BK7 lens element

- Convex array lens element

- Laser lens element

- Crystal lens element

- Silica lens element

- Spherical lens element

- Round optical window

- UV lens element

- Fused silica lens element

- Laser mirror

- Plano-convex lens element

- Cylindrical lens element

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.