- Hydraulics - Pneumatics

- Filter and Separator

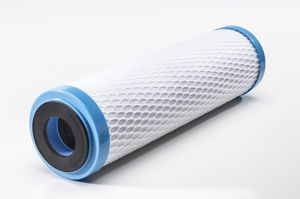

- Solvent filter cartridge

- Allied Filter Systems Ltd

Pleated filter cartridge Econopleat seriesfor solventswaterfine

Add to favorites

Compare this product

Characteristics

- Media

- water, for solvents

- Type of filtration

- fine

- Material

- polypropylene

- Applications

- for general purposes

- Domain

- industrial

- Other characteristics

- pleated

- Removal rating

Max.: 50 µm

Min.: 2 µm

Description

Pleated filter cartridges are surface filters for removing hard, non-deformable particles from a liquid stream. They feature a large filter area, a high dirt holding capacity and consequently a long filtration lifetime. The sharp cut-off characteristics created by the filter media ensures dependable and highly efficient particle removal at the designated micron rating. Pleated filter cartridges are therefore widely used as particle size classification filters, as well as being utilised as either final filters or as protection for expensive membrane filter cartridges.

The Econopleat series of pleated cartridges consist of 3 layers of filter media, resulting in a high surface area cartridge that performs well with high flow rates, whilst achieving a good dirt holding capacity with no compromise to operational pressure drops.

Econopleat PP : 100% polypropylene melt blown filter media with thermally bonded end caps.

Econopleat GF : Borosilicate media with polypropylene support layers with thermally bonded end caps.

Econopleat PE : Polyester media with polypropylene end caps

Surface area : >0.34m2 per 10” length.

4 7/8” to 40” lengths.

Single piece construction.

Standard ID. 27.5mm OD. 69mm.

Large outer diameter 116mm versions available, 10” – 40”.

Available micron ratings (@ 95% efficiency): Econopleat PP: 2 – 50 micron. Econopleat GF: 2,5 10,20. Econopleat PE: 5,10,20,50

Polypropylene core and polypropylene end caps (for all media).

End fittings : Double open ended with flat gaskets, Code 3, Code 7, Code 8.

Gasket materials : Nitrile, EPDM, Viton, Silicone, PTFE encapsulated Viton, PTFE encapsulated Silicone.

Catalogs

No catalogs are available for this product.

See all of Allied Filter Systems Ltd‘s catalogsOther Allied Filter Systems Ltd products

Filter Cartridges & Housings

Related Searches

- Liquid separator filter

- Filter cartridge

- Industrial filter cartridge

- Pressure separator filter

- Filter for industrial applications

- Fine filter cartridge

- Filter housing

- Filtration system

- General purpose filter cartridge

- Water filter cartridge

- Cartridge filter housing

- Liquid filter housing

- Polymer filter cartridge

- Filter element

- Liquid filtration system

- Basket separator filter

- Metal filter housing

- Stainless steel filter housing

- Process separator filter

- Pleated filter cartridge

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.