- Machine-tools

- Cutting Tool

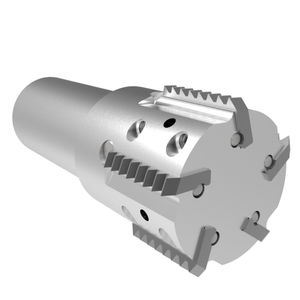

- Solid carbide milling cutter

- Allied Machine & Engineering

Solid carbide milling cutter ThreadMills USA®threadwith TiAlN coatingfor cast iron

Add to favorites

Compare this product

Characteristics

- Construction

- solid carbide

- Type

- thread

- Material

- with TiAlN coating

- Treated material

- for cast iron, for stainless steel, for hardened steel, for aluminum

- Other characteristics

- left-hand

Description

Thread mills drastically reduce the occurrences of scrap when compared to taps, which makes them desirable when manufacturing large and/or costly components. ThreadMills USA® is an economic thread milling product backed by Allied’s experienced technical staff and provides quality threads when compared to other thread making processes. ThreadMills USA® is an Allied Machine & Engineering Company known for producing high-quality thread mills.

Advantages

Quality thread mills at an affordable price

One tool can cut right- and left-hand threads

Increased strength and rigidity when cutting forces are applied

Standard cutting lengths accommodate multiple applications without the need for an engineered special

Reduced chipping and longer tool life in blind hole applications when using coolant through

Resharpening service available

Features

TiAlN coating

Thicker core

Helical flutes

Wide range of forms and pitches

Imperial and metric shanks

Coolant through

Online programming

Catalogs

Related Searches

- Milling tool

- Solid milling tool

- Drilling tool

- Steel milling tool

- Solid drilling tool

- Metal milling tool

- Coated milling cutter

- Cast iron milling tool

- Indexable cutting insert

- General purpose drill bit

- Cutting milling tool

- Solid carbide milling tool

- Carbide drilling tool

- Aluminum milling tool

- Stainless steel milling tool

- High-speed steel drill bit

- Hardened steel milling tool

- Turning indexable cutting insert

- Steel drilling tool

- Cast iron drilling tool

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.