- Hydraulics - Pneumatics

- Filter and Separator

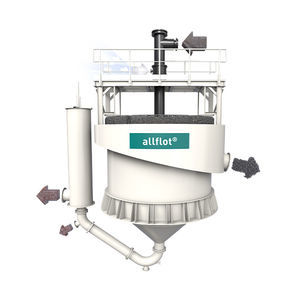

- Air separator

- allmineral Aufbereitungstechnik GmbH & Co.KG

Air separator alljig®liquidscoalprocess

Add to favorites

Compare this product

Characteristics

- Technology

- air

- Separated substance

- liquids, coal

- Application domain

- process, for ore

- Other characteristics

- automatic

Description

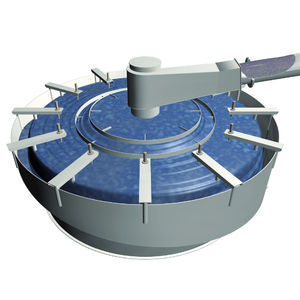

With its broad feed-in spectrum, the alljig® ensures efficient sorting of a wide variety of primary and secondary raw and waste materials featuring different densities. The water- and air-pulsed alljig® is a smart, reliable and economical solution.

Precise automatic discharge regulation to ensure consistently high product quality

Special designs for 1 to 4 separations in a single machine

12 different machine widths for range of feed material levels

Numerous configuration options for optimising the sorting process – even during operation

As alljig® jigs are air-pulsed, the pulsation of water is practically wear-free and offers broad scope for configuration and optimisation.

The second core process is that of discharging – the separation of the heavy feed from the layered material bed. This is performed via the heavy feed discharge from a storage layer. The separation layer is scanned by a ‘floater’, which precisely traces the behaviour of the heavy feed layer awaiting separation. The signals from the floater are detected and processed electronically.

Sieve discharges, pivoting beds, bottom slide discharges and rotary valves may be used as discharge devices depending on the raw material type and the grain size.

VIDEO

Catalogs

alljig® brochure

8 Pages

Other allmineral Aufbereitungstechnik GmbH & Co.KG products

wet processing

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.