- Hydraulics - Pneumatics

- Filter and Separator

- Gravity separator

- allmineral Aufbereitungstechnik GmbH & Co.KG

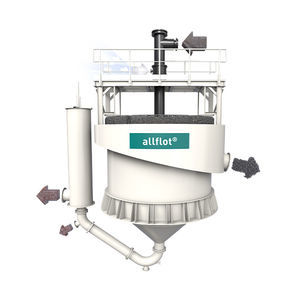

Gravity separator allflux®sludgeprocesscompact

Add to favorites

Compare this product

Characteristics

- Technology

- gravity

- Separated substance

- sludge

- Application domain

- process

- Other characteristics

- compact, wet, circular, classifier

- Flow

2,000 m³/h

(70,629.333 ft³/h)- Filtration size

4 mm

(0.157 in)

Description

The allflux® procedure uses fluidised bed technology for density sorting and hydraulic classification. This two-stage treatment makes it possible to process a mixture of sand and water without pre-thickening. An upflow that passes through the feed slurry at the coarse sand level causes the light and fine particles to rise up, with the sinking coarse and heavy particles being removed.

The fine sand level, a circular process that constitutes the second stage, is reached by the light material – including the fine particles that form an autogenous fluidised bed. The light material awaiting separation floats on this bed and subsequently spills over with the upflow of water.

Sorting, classification, thickening and cleaning all performed in a single unit

Production of quality sand from deposits featuring impurities

Consistent material quality via automatic process control

Low energy requirement and low wear

Thanks to the new generation of control software and a whole host of additional improvements, the allflux® fluidised bed sorter not only reliably separates organic impurities but also produces and mixes high-precision sand fraction classes. This means that compact plants requiring low investment and operating costs can generate high-quality sands according to a recipe, even when using partial flows in existing facilities.

Since the market launch of the allflux® fluidised bed procedure in the sand and concrete industry, this technology has been successfully used in numerous other application areas.

VIDEO

Catalogs

alljig® brochure

8 Pages

Other allmineral Aufbereitungstechnik GmbH & Co.KG products

wet processing

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.