- Environment - Health - Safety

- Water Treatment

- Compact flotation plant

- allmineral Aufbereitungstechnik GmbH & Co.KG

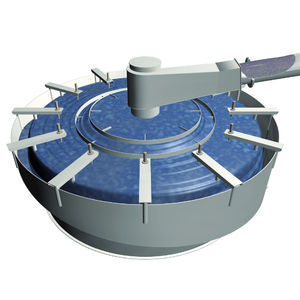

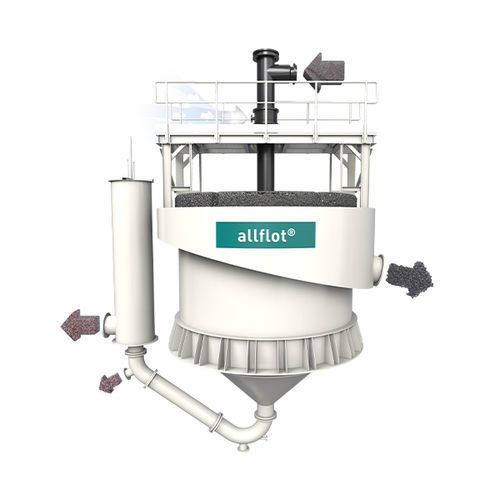

Compact flotation plant allflot®

Add to favorites

Compare this product

Characteristics

- Options

- compact

Description

The unique allflot® machine increases both the yield and quality of minerals. It features an innovative new ventilation concept crafted by our engineers and offers the maximum possible flexibility in terms of the volumetric throughput rate.

Highly efficient and flexible use of flotation technology for high-quality mineral enrichment

Energy-efficient, space-saving solution

Adjustable air bubble size and volume for improved product purity and increased mineral yield

Long-lasting investment thanks to ceramic nozzles with a service life of over 10,000 hours for mineral enrichment and over 40,000 hours for coal processing

The revolutionary technology of the allflot® processing plant enables the sustainable processing of minerals. As allflot® does not feature any rotating machine components, it offers significant savings compared with conventional plants: its energy costs are 30% lower than those of a processing plant featuring mechanical agitator flotation.

allflot® uses direct current and combines the principles of upflow and flotation. Working in combination with the unique channel discharge system, it additionally supports the efficient processing of coarser mineral particles. The innovative foam channel discharge system ensures that coarse particles are floated out. We deploy the channel discharge system wherever high foam yields are expected. In the context of low foam yields, such as those witnessed in various fields of ore flotation, a centric displacement cone serves to increase the foam thickness and thus enables maximum selectivity.

VIDEO

Catalogs

No catalogs are available for this product.

See all of allmineral Aufbereitungstechnik GmbH & Co.KG‘s catalogsOther allmineral Aufbereitungstechnik GmbH & Co.KG products

wet processing

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.